ORAFOL has been offering screen printing services for standard traffic signs and customised retroreflective solutions for over 15 years.

Printing Technology

Screen printing as a service

Retroreflective sign faces are manufactured at the headquarters in Oranienburg in the highest print quality – using state-of-the-art screen printing technology and integrated full service.

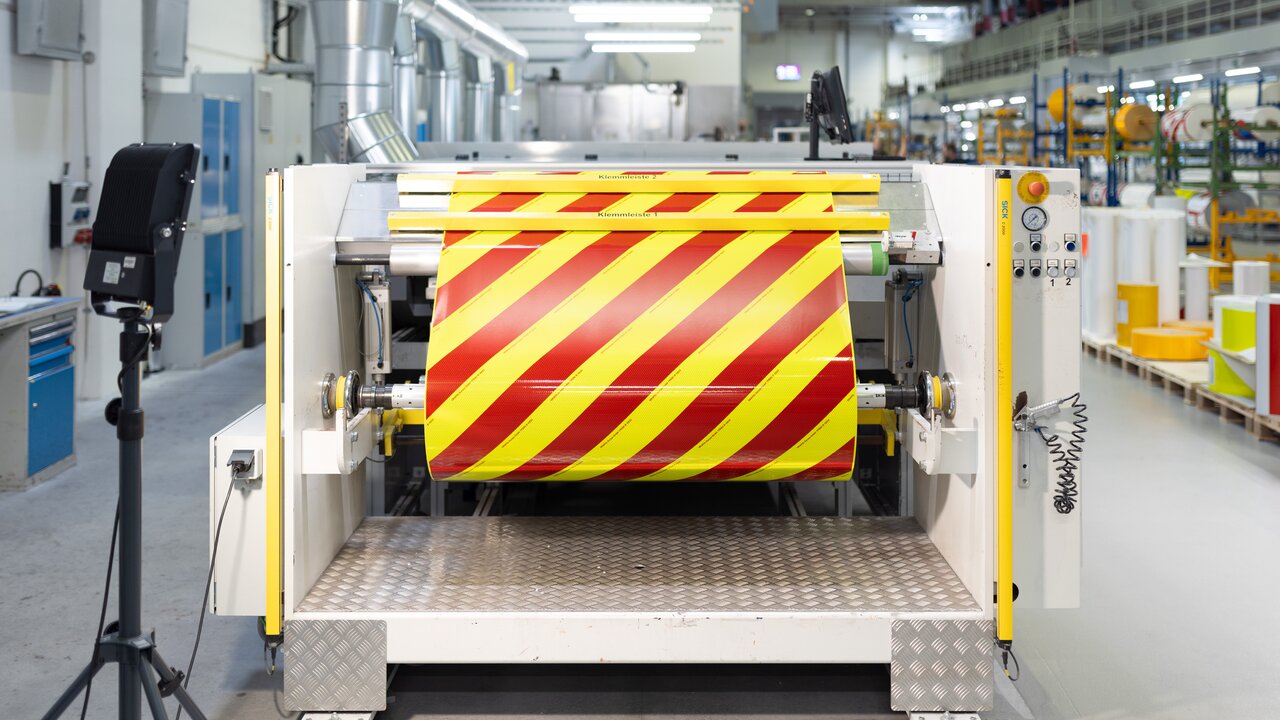

ORAFOL offers efficient and reliable production of retroreflective signal face materials for traffic signs using industrial screen printing. At its headquarters in Oranienburg, state-of-the-art screen printing technology is used that has been specially developed for processing ORALITE® retroreflective films and ORALITE® screen printing inks.

The combination of certified materials, process-optimised technology and technical expertise ensures consistently high print quality, regardless of print run size or design complexity. This allows standardised traffic signs, customer-specific and graphic layouts to be implemented economically and in accordance with standards.

Efficient production of retroreflective sign faces

ORAFOL operates highly efficient two-colour screen printing systems at its headquarters in Oranienburg. The combination of advanced technology and comprehensive service ensures maximum cost-effectiveness for medium to high print runs, as well as excellent reproducibility of print results.

ORAFOL screen printing technology was developed specifically for printing on ORALITE® brand retroreflective special films. Our certified materials and screen printing inks are precisely matched to the industrial screen printing system – for optimal printing results with high transparency, UV resistance and long-lasting functionality – regardless of print run size or design complexity.

Strong partner in screen printing with high technology

Certified products are manufactured using screen printing exclusively at the company's headquarters in Oranienburg. State-of-the-art two-colour screen printing systems enable two colours to be applied in a single production run. Combined with automated processes, technical expertise and documented quality management in accordance with ISO 9001, this ensures consistent print quality.

Industrial screen printing

Screen printing is considered a proven method for producing sign faces in medium to high quantities. ORAFOL produces sign faces of consistently high quality in an industrially controlled environment with defined room temperature, regulated humidity and optimised air circulation and filtration.

The "everything from a single source" principle, consisting of ORALITE® reflective films (microprismatic and glass bead based), ORALITE® screen printing ink and process-optimised printing technology, ensures that all components required for screen printing are available and optimally matched to each other.

This certified complete package from ORAFOL guarantees premium quality and on-time delivery, even for large series orders.

Certified quality and sustainable processes

ORAFOL is certified according to ISO 9001 (quality management) and ISO 14001 (environmental management). These internationally recognised standards form the basis for consistent quality and environmental management at the Oranienburg site.

The screen printing processes are continuously monitored in accordance with regulatory requirements and checked for quality, safety and reliability through annual CE audits to ensure consistently high product quality in line with sustainable practices.

Signal image materials are manufactured in accordance with RAL quality standards with our own rights of use and the required internal and external monitoring, and thus meet all the requirements of national and international standards, such as European standard EN 12899-1 and international standard ASTM D4956.

Holistic solutions and one-stop service

ORAFOL's service portfolio ranges from technical consulting and the selection of suitable materials to assembly and worldwide delivery – individual requirements are taken into account as well as standardised applications. ORAFOL guarantees reliable implementation at the highest level through technical expertise, project-related consulting and consistent compliance with relevant standards.

Full service from consulting to delivery

Customers benefit from a comprehensive one-stop service – from technical advice and the selection of suitable ORALITE® premium films in all reflection classes to sampling and worldwide delivery. The comprehensive service portfolio also includes advice on functional laminates with anti-graffiti, anti-dew or anti-sticker surface.

In addition to standardised layouts, individual customer solutions with logos, special markings or watermark impressions, including print template creation, can also be implemented. Regional standards and approval requirements are consistently taken into account throughout the project. An experienced team of experts is on hand to provide advice throughout the entire project.

Packaging and delivery as required

Delivery is flexible according to customer requirements: as a large roll for further processing, as a ready-made sign face for further processing, or as a completely ready-to-use sign face for direct application to the sign substrate. All sign faces produced by ORAFOL bear the manufacturer's identification ‘05’ for clear traceability.

Facts & Figures

Usefull informations about screen printing services

- Two-colour screen printing system: efficient printing of two colours in a single production run.

- Finishing: combination with digital printing and lamination for customisation and protection.

- Packaging: delivery either as a large roll (unprinted, printed in one or two colours) or as cut-to-size sign face (unprinted, printed in one or two colours).

- High reproducibility: consistent print quality, regardless of print run size or design complexity.

- Customisation: integration of standard markings, customer-specific logos or watermark impressions.

Reflective films from the ORALITE® brand

- Approvals: fulfilment of all relevant requirements for CE approval and the US standard ASM.

- Technology: choice of microprismatic or glass bead based reflective technology – tailored to the respective application.

- Reflection classes: available in RA3, RA2 and RA1 – in accordance with international standards.

- Film colours: standard colours such as white and yellow as well as numerous special colours available.

- Ink compatibility: printable with solvent-based and UV-curing screen printing inks.

- Available widths: standard widths such as 610 mm, 1220 mm, other widths on request.

- Liner design: optionally neutral or with print image (e.g. brand labelling).

Accessories: special films, protective laminates and screen printing inks

- ORALITE® 5018 Screen Printing Ink: high-performance screen printing ink, compatible with all ORALITE® reflective films.

- ORALITE® 5081 / 5071 Lettering Film: for durable lettering and marking of traffic signs.

- ORALITE® 5061 / 5051 Transparent Film: for colour design or UV protection of ORALITE reflective films.

- ORALITE® 5097 Astifol® Anti-Sticker: special laminate to prevent the application of stickers.

- ORALITE® 5090 Anti-Dew Film: functional laminate with anti-dew effect, prevents condensation on traffic signs.

- ORALITE® 5095 Anti-Graffiti Film: protective laminate against graffiti contamination, easy to clean, permanently effective.