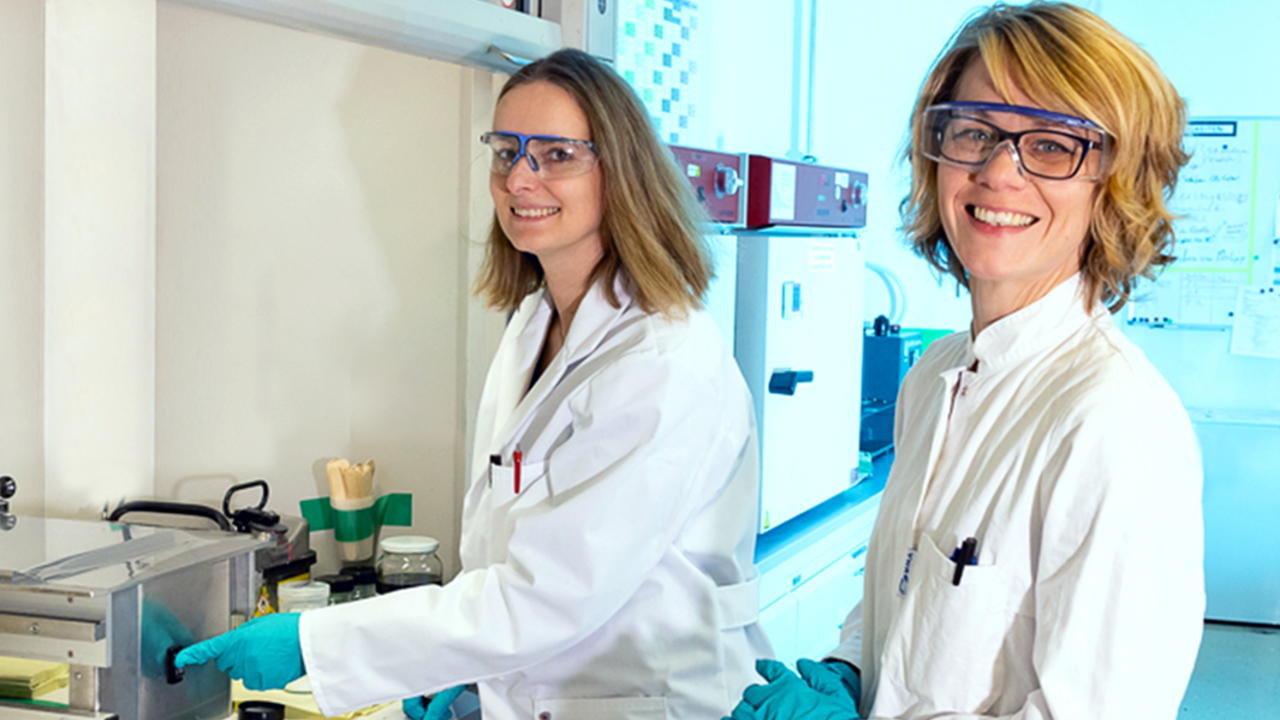

Joint-friendly, hoof-friendly, non-slip – this is how one manufacturer promotes its rubber mats for livestock transport vehicles. These mats are installed on loading ramps to prevent horses from slipping and getting injured during loading. A seemingly inconspicuous product – yet one with a very concrete application for ORAFOL’s Adhesive Tape Systems: How does the rubber mat adhere optimally to the steel surface of the ramp? “That was the starting point of our development task,” explains Dr Sandra Starke, R&D Scientist Adhesive Tape Systems, referring to one of her projects. “The challenge lay in the substrate: rubber. It often contains substances that migrate into the adhesive layer and impair its bond – our solution must be resistant to this, mechanically robust and durably adhesive.”

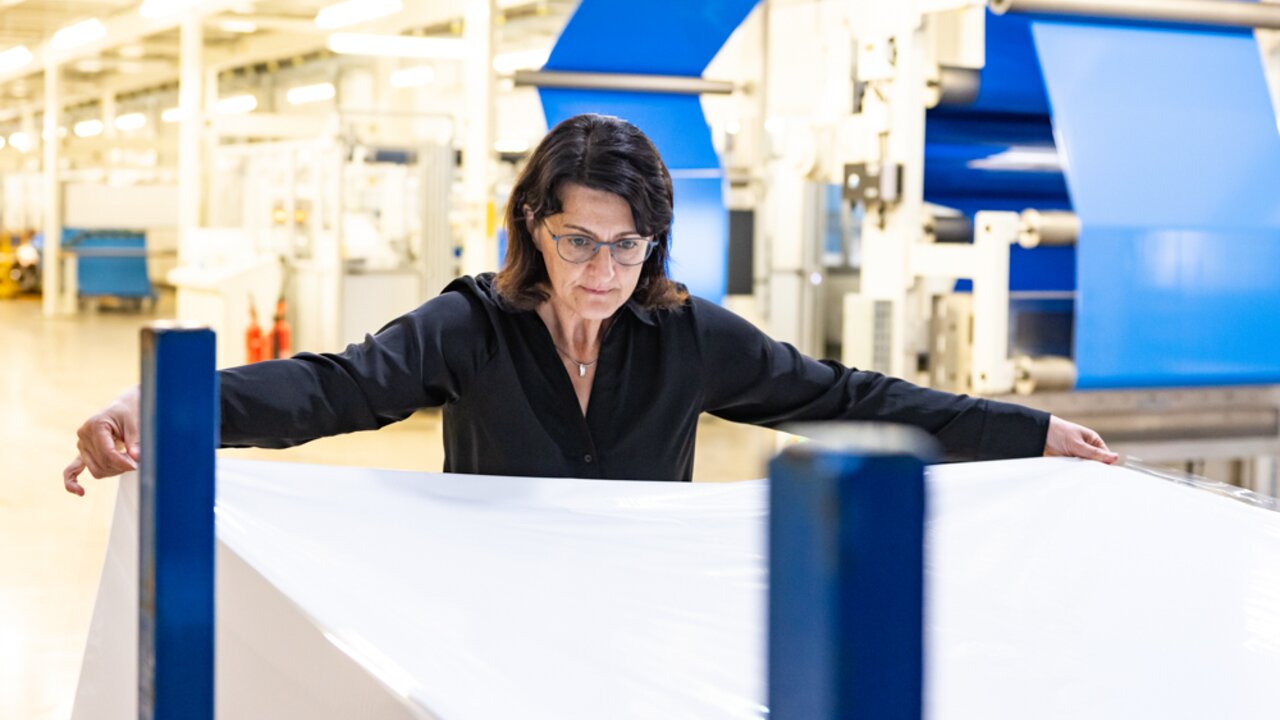

For such specialised requirements, ORAFOL develops acrylic dispersions tailored to diverse customer needs. These adhesive solutions are coated onto carrier materials at the Oranienburg site, converted, delivered, and laminated by the customer onto the substrate. “Here, we draw on decades of experience. No two adhesive solutions are alike.”