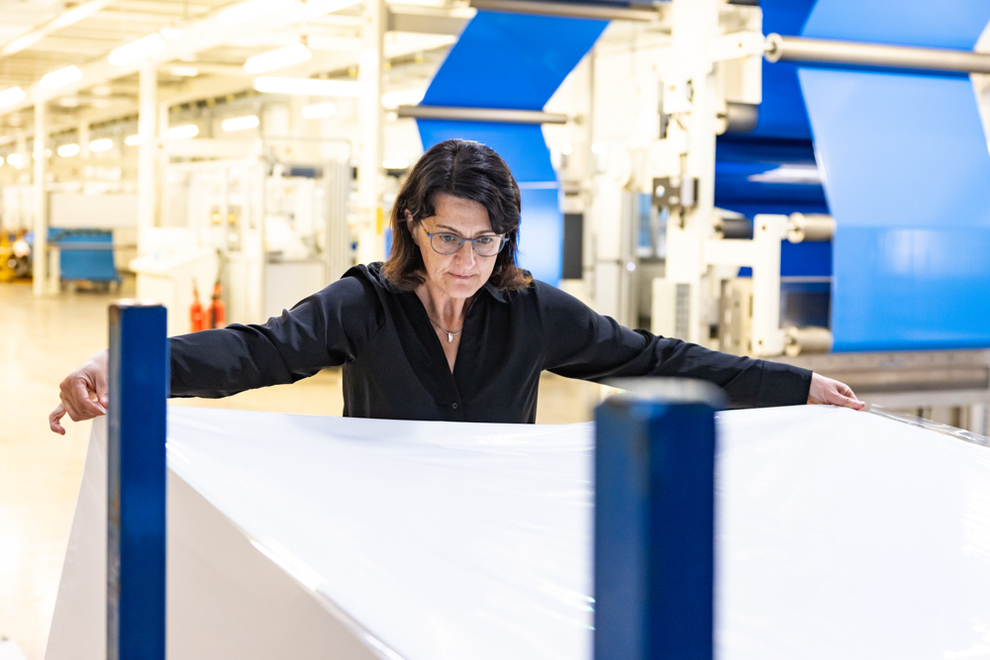

It is just after eight o’clock when Stéphanie Robert begins the quality inspection in Hall 7 at the Oranienburg headquarters together with a colleague. In front of them are rows of film rolls with markings: products that must be inspected before further processing in the plant. “This way we can prevent customers from receiving defective goods,” says Robert as she examines a film. For the experienced quality manager, these rounds are an early warning system: they reveal where processes or machines may be getting out of sync and where action is required. The walk-throughs are only a small part of her working day, but they illustrate how Robert understands quality: as an ongoing process, not merely a final inspection.

Quality from A to Z

Stéphanie Robert heads Quality Assurance in the Graphic Solutions division at ORAFOL. With clear processes, technical expertise, and close collaboration, she and her colleagues work to ensure that the company’s high quality standards are maintained.

From Research into Quality

Robert came to quality assurance by way of a detour. She studied biology and initially worked for more than 20 years in research and development at a food manufacturer, before also taking on the responsibility for quality assurance in parallel. When later faced with the decision between the two fields, she chose quality assurance: “If you work preventively, you can avoid errors – and that is very motivating for me.” Three years ago, Robert joined ORAFOL, where she now leads quality assurance in the Graphic Solutions division.

Ensuring Quality – from Standards to Audits

Robert’s responsibilities are wide-ranging: she develops and implements quality standards, prepares inspection plans, evaluates results, and defines corrective measures. She also organizes employee training, coordinates supplier audits within her division, and plans visits. For example, with “critical” suppliers – new partners or those with an above-average complaint rate. In such cases, Robert visits the supplier together with the purchasing team to review processes on-site. This is based on a previously agreed audit plan, tailored to past experiences and specific findings. The audits usually last a full day and are aimed not only at identifying weaknesses but also at developing constructive corrective measures. Robert explains: “We see our suppliers as partners with whom we work on equal footing. Only if we talk openly about problems and share our know-how can we achieve improvements together and ensure stable quality in the long term.”

Teamwork as a Success Factor

“Even internally, a quality department cannot achieve anything on its own,” Robert emphasizes. Weekly Tuesday meetings bring together all relevant departments. In advance, Robert and her team analyze anomalies – from production data and serial numbers to adhesion values – and prepare solution approaches. “This way we enter the meetings with a clear basis, and everyone can discuss as equals.” Her own background in development helps her to ask the right questions and set priorities.

Technologies for Greater Precision

Digitalization and modern technology are transforming the work. The introduction of SAP has made quality assurance analysis more transparent and provides a solid foundation for continuous improvement. The planned implementation of an automatic web inspection system, for example for paint protection films – a camera-based system that automatically detects defects – is expected to further improve the detection of deviations. “You have to train the system like a new colleague,” says Robert. “In the end, it should recognize all deviations and automatically reduce waste.” She sees successful ISO 9001 audits as confirmation: “An external party examines us and confirms that we are operating at a high level.”