Retroreflective Materials

Retroreflectivity is the scientific term that describes the ability of an object to redirect light back to its source. A typical example of Retroreflectivity is seen when the light from automobile headlights are redirected to the drivers eyes from traffic signs at night. Examples of retroreflective materials are traffic control signs, vehicle markings; and personal safety items such as vests.

For over 55 years ORAFOL has been a pioneer and technology leader in the development of the brightest retro-reflective materials in the world.

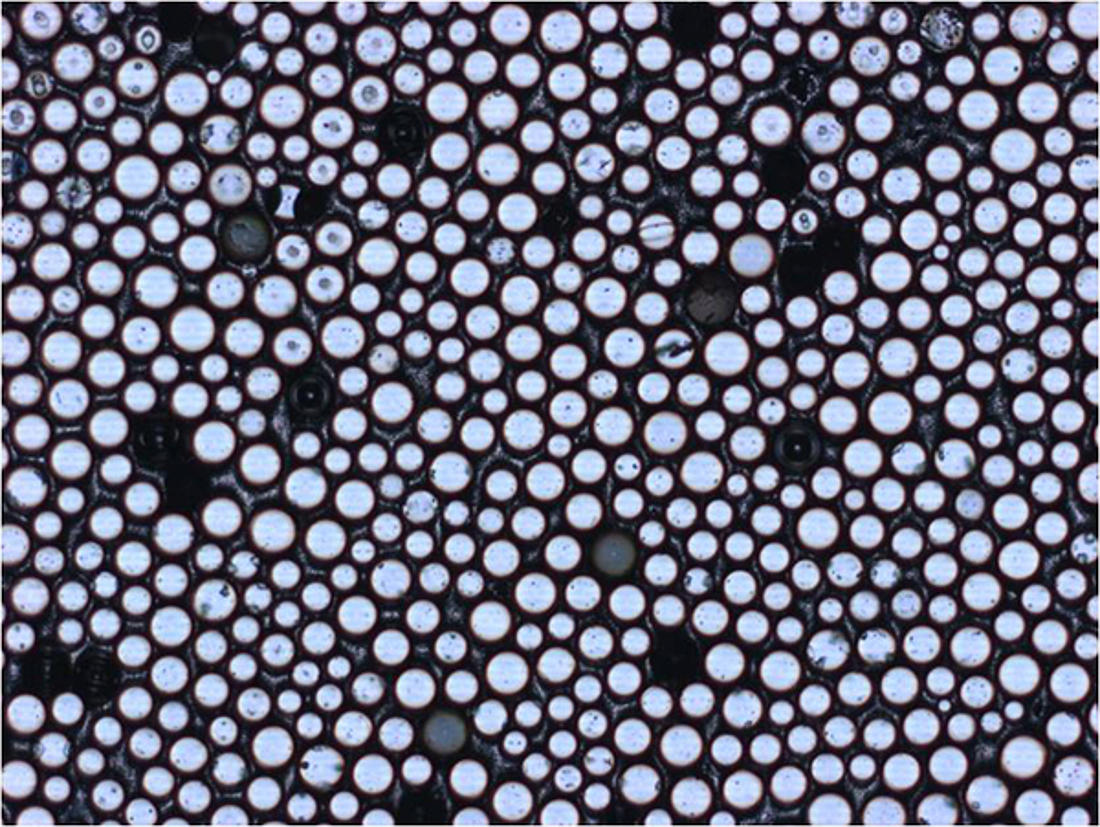

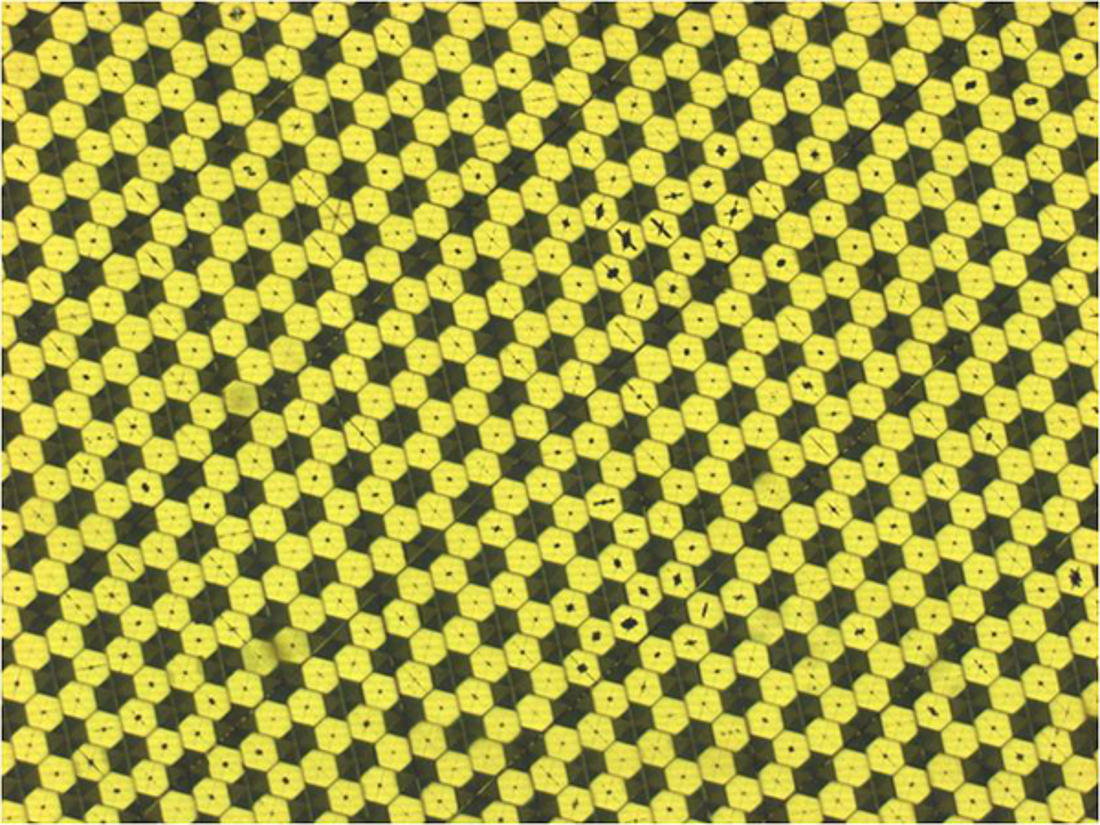

Retroreflective materials use one of two technologies to provide the retroreflection: glass-beads or cube corner microprisms.

ORAFOL Americas - GA

1100 Oracal Parkway

Black Creek, GA 31308

912-851-5000

Toll Free | 888-672-2251

ORAFOL Americas - CT

120 Darling Drive

Avon, CT 06001

860-676-7100

Toll Free | 800-654-7570

ORAFOL Canada

2831 Bristol Circle

Oakville, ON L6H 6X5

905-829-2828

Toll Free | 888-727-3374