Videos

![]() 2024 ORAFOL + KPMF Vehicle & Wrap Training Certification

2024 ORAFOL + KPMF Vehicle & Wrap Training Certification![]() ORAJET 3551RA+ProSlide® Promo

ORAJET 3551RA+ProSlide® Promo![]() ORAJET 3551RA+PS Full Tutorial from The Wrap Institute

ORAJET 3551RA+PS Full Tutorial from The Wrap Institute![]() ORAJET 3971RA+PS The Industry's First Cast Polyurethane non-PVC Wrapping Film

ORAJET 3971RA+PS The Industry's First Cast Polyurethane non-PVC Wrapping Film![]() The Industry's First Cast Polyurethane non-PVC Wrapping Film

The Industry's First Cast Polyurethane non-PVC Wrapping Film![]() Episode 1, Wrap Shop Benefits of ORAJET® 3971RA+ProSlide® and ORAGUARD® 279G + SG

Episode 1, Wrap Shop Benefits of ORAJET® 3971RA+ProSlide® and ORAGUARD® 279G + SG![]() Episode 2, Vehicle Owner Benefits, ORAJET® 3971RA+PS and ORAGUARD® 279G + SG

Episode 2, Vehicle Owner Benefits, ORAJET® 3971RA+PS and ORAGUARD® 279G + SG![]() TechnoWraps + ORAJET® 3971RA+PS

TechnoWraps + ORAJET® 3971RA+PS![]() ORAJET 3105HT Application Video

ORAJET 3105HT Application Video![]() NEW ProSlide™ Advanced Repositionable Adhesive Technology

NEW ProSlide™ Advanced Repositionable Adhesive Technology![]() AAV3D + ORAFOL Digital Swatchbook

AAV3D + ORAFOL Digital Swatchbook![]() ORAFOL + KPMF Vehicle Wrap Training & Certification Fall 2023

ORAFOL + KPMF Vehicle Wrap Training & Certification Fall 2023![]() ORAFOL + XIX3D Digital Swatchbook

ORAFOL + XIX3D Digital Swatchbook![]() Episode 1 - ORACAL 851 Rally Stripe Application Video

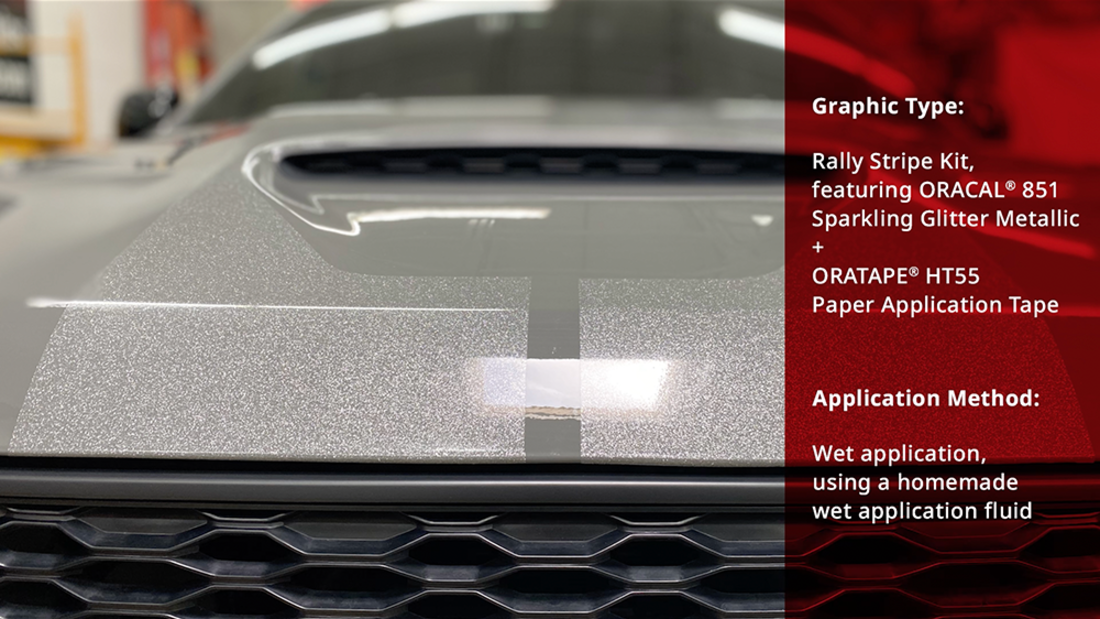

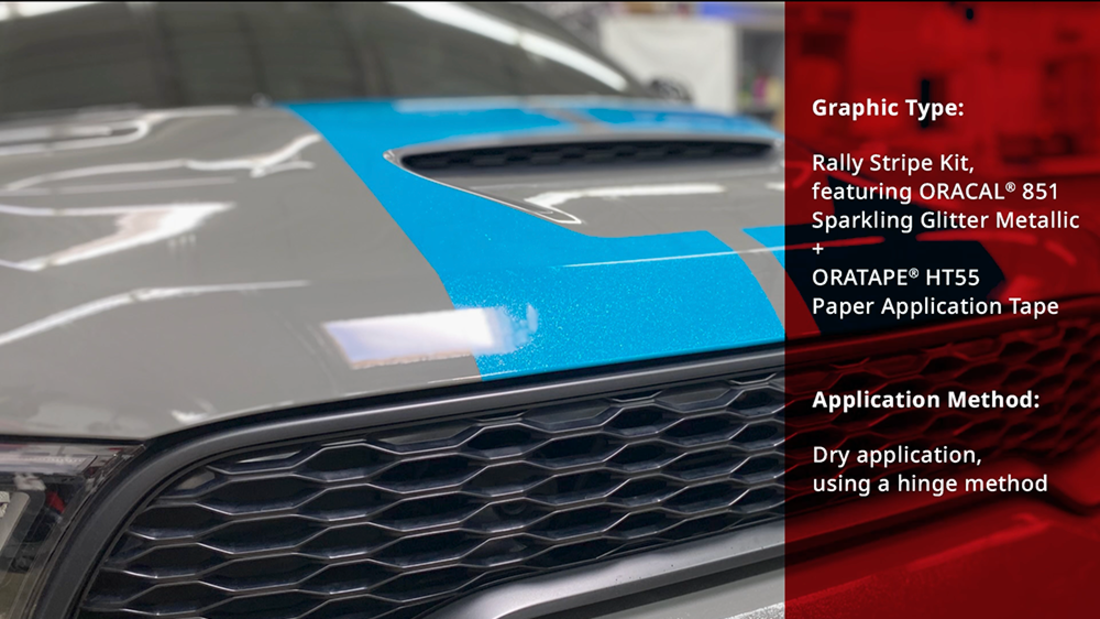

Episode 1 - ORACAL 851 Rally Stripe Application Video![]() Episode 2 - ORACAL 851 Rally Stripe Application Video

Episode 2 - ORACAL 851 Rally Stripe Application Video![]() Episode 3 - ORACAL 851 Rally Stripe Hood Application

Episode 3 - ORACAL 851 Rally Stripe Hood Application![]() Episode 1 - Adhesive Technology Series: Removable Adhesives

Episode 1 - Adhesive Technology Series: Removable Adhesives![]() Episode 2 - Adhesive Technology Series: Permanent Adhesives

Episode 2 - Adhesive Technology Series: Permanent Adhesives![]() Episode 3 - Adhesive Technology Series, Permanent High-Tack Adhesives

Episode 3 - Adhesive Technology Series, Permanent High-Tack Adhesives![]() Downloading ORAJET ICC Profiles

Downloading ORAJET ICC Profiles![]() Episode 1 - This vs That, ORAGUARD 210 vs 215 Video

Episode 1 - This vs That, ORAGUARD 210 vs 215 Video![]() Episode 2 - This vs That, ORAGUARD 290 vs ORAGUARD 293

Episode 2 - This vs That, ORAGUARD 290 vs ORAGUARD 293![]() Episode 3 - This VS That, Fleet Engineer Grade Reflective VS Flexible Prismatic Reflective Sheeting

Episode 3 - This VS That, Fleet Engineer Grade Reflective VS Flexible Prismatic Reflective Sheeting![]() Episode 4 - This VS That, ORAJET 3164 vs ORAJET 3165

Episode 4 - This VS That, ORAJET 3164 vs ORAJET 3165![]() Episode 5 - This VS That, ORAJET 3641 VS ORAJET 3621

Episode 5 - This VS That, ORAJET 3641 VS ORAJET 3621![]() Episode 6 - This VS That, ORAJET 3551RA VS ORAJET 3951RA + PS

Episode 6 - This VS That, ORAJET 3551RA VS ORAJET 3951RA + PS![]() Episode 7 - This VS That, Cast VS Calendered

Episode 7 - This VS That, Cast VS Calendered![]() Episode 8 - This VS That, ORALITE Prismatic Trim VS ORALITE Glass Bead Trim

Episode 8 - This VS That, ORALITE Prismatic Trim VS ORALITE Glass Bead Trim![]() ORALITE® Vehicle Conspicuity Tape

ORALITE® Vehicle Conspicuity Tape![]() ORAFOL + Eastern Metal UV Digital Traffic Sign Printer

ORAFOL + Eastern Metal UV Digital Traffic Sign Printer![]() ORALITE Prismatic Trim Technology

ORALITE Prismatic Trim Technology![]() ORAFOL Certified Installer Spotlight with Cary Siegler, Owner of GT3 Creative

ORAFOL Certified Installer Spotlight with Cary Siegler, Owner of GT3 Creative![]() ORAFOL Certified Installer Spotlight with Joseph Price, Owner of Artworks Commercial Graphics

ORAFOL Certified Installer Spotlight with Joseph Price, Owner of Artworks Commercial Graphics![]() ORAJET 1917 Project Video

ORAJET 1917 Project Video![]() ORAFOL + PDAA Wall Alignment Panel Tips

ORAFOL + PDAA Wall Alignment Panel Tips![]() Lexus + ORAFOL

Lexus + ORAFOLNEW ORACAL 8300 & 8510 Architectural Window Graphic Application

![]() ORAJET 3751RA + ProSlide™

ORAJET 3751RA + ProSlide™![]() Andretti Autosport + ORAFOL

Andretti Autosport + ORAFOLNEW ORAJET 3169RA - Window, Wall & Floor Application Video

![]() Cold Temperature Graphic Installations

Cold Temperature Graphic Installations![]() ORACAL 631 Exhibition Cal Corporate Installation

ORACAL 631 Exhibition Cal Corporate Installation![]() ORALITE Prismatic Trim Technology

ORALITE Prismatic Trim Technology![]() AGFA Anapurna H1650i LED

AGFA Anapurna H1650i LED![]() ORALITE V98 Reflective Chevron Striping Application Video

ORALITE V98 Reflective Chevron Striping Application Video![]() ORACAL 820 Anti-Tamper Vinyl

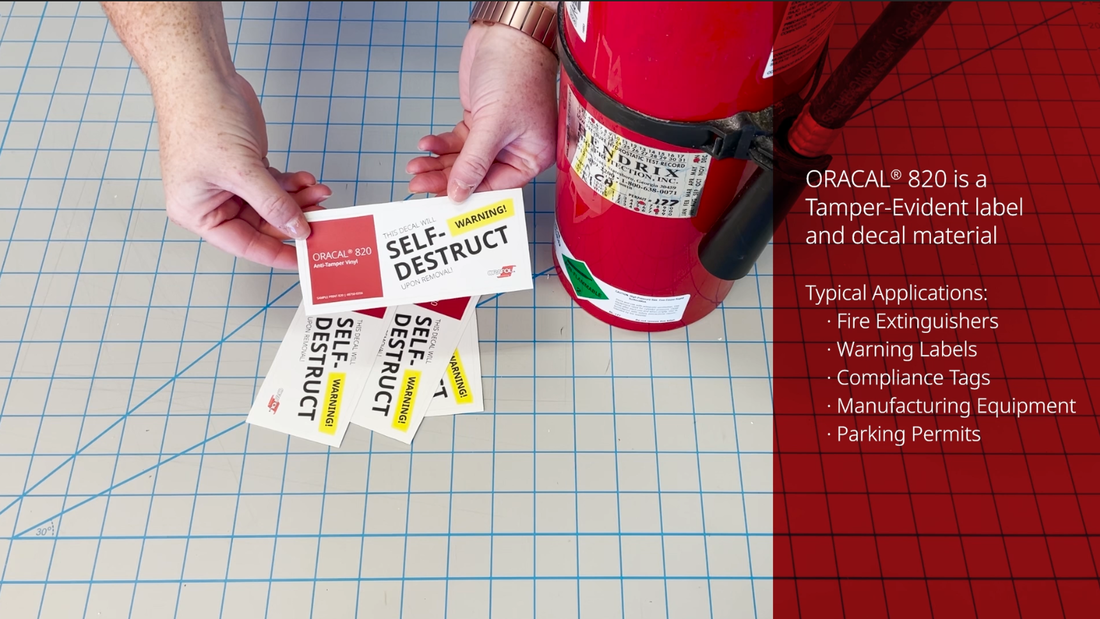

ORACAL 820 Anti-Tamper Vinyl![]() ORACAL 851 Screen Printing Glitter Stickers

ORACAL 851 Screen Printing Glitter Stickers![]() ORAJET 3952F Application Video

ORAJET 3952F Application VideoNEW ORACAL 970RA Vehicle Wrap Application Video

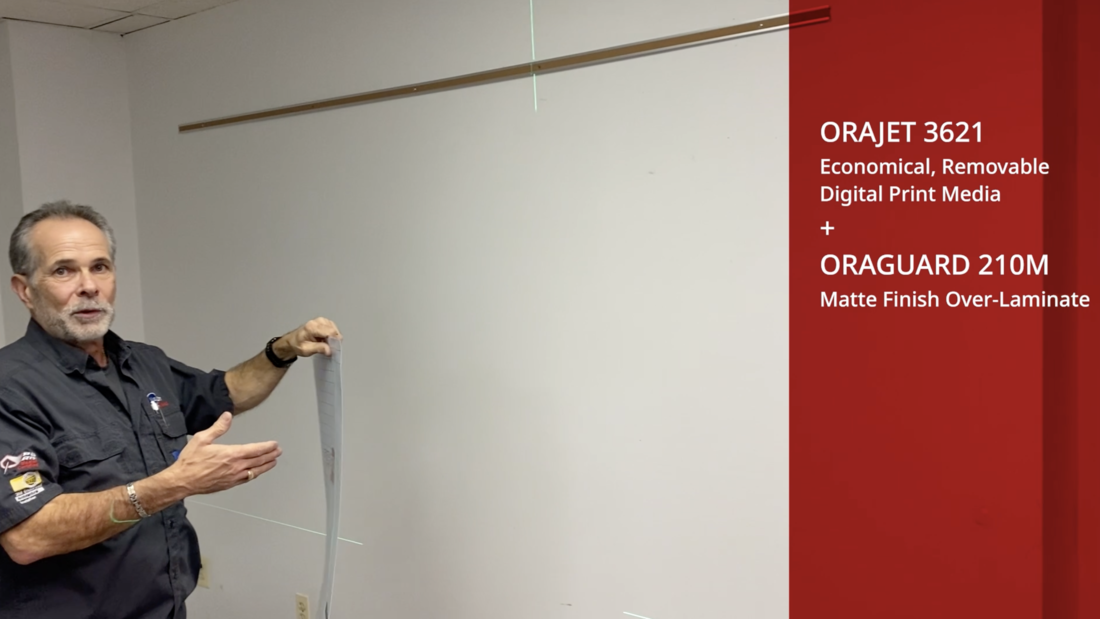

ORAFOL Education Series Training Video - Hinge Install Method

ORAMASK 813 Paint Stencil Film

ORATAPE MT95 Application Tape

NEW ORAJET 3954 Brick & Stone Textured Wrap Film Application Video

![]() NEW ORALITE V98 Application Video

NEW ORALITE V98 Application VideoNEW ORALITE 5600RA Fleet Engineer Grade Reflective Wrap Film Application Video

NEW ORAGUARD 289F Over-Laminate / PPF Self-Healing & Puncture Demonstration

![]() Wrapping Door Handles with Jim Miller

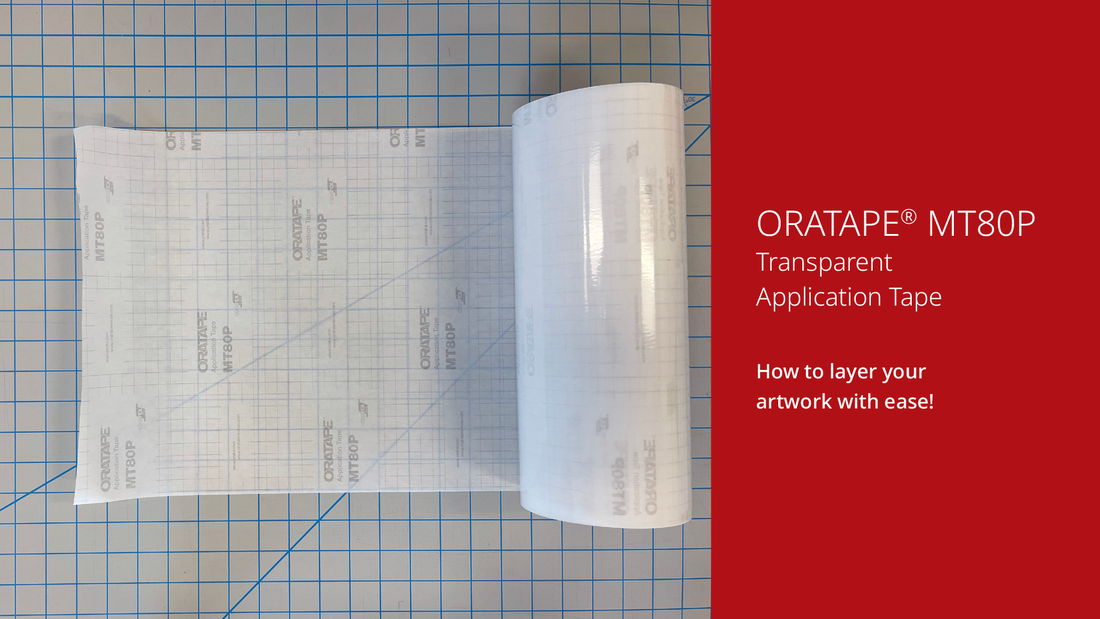

Wrapping Door Handles with Jim Miller![]() NEW ORATAPE MT80P Application Tape

NEW ORATAPE MT80P Application Tape![]() NEW ORAGUARD 215DU

NEW ORAGUARD 215DU![]() NEW ORACAL 970RA UNIQUE Colors by Will Castro Designs

NEW ORACAL 970RA UNIQUE Colors by Will Castro Designs![]() ORAFOL Semi Wrap

ORAFOL Semi Wrap![]() ORACAL 970RA Premium Shift Effect Cast

ORACAL 970RA Premium Shift Effect Cast![]() ORAJET 3930 Photoluminescent

ORAJET 3930 Photoluminescent![]() ORACAL 820 Safety Vinyl

ORACAL 820 Safety Vinyl![]() ORACAL 970RA Premium Wrapping Cast

ORACAL 970RA Premium Wrapping Cast![]() ORAMASK 813 Happy Thanksgiving Door Hanger

ORAMASK 813 Happy Thanksgiving Door Hanger![]() ORACAL 631 Sweater Weather Coffee Mug

ORACAL 631 Sweater Weather Coffee Mug![]() Get Game Day Ready with ORAFOL

Get Game Day Ready with ORAFOL![]() ORACAL 851 + ORALUX 9300 Halloween Wood Sign

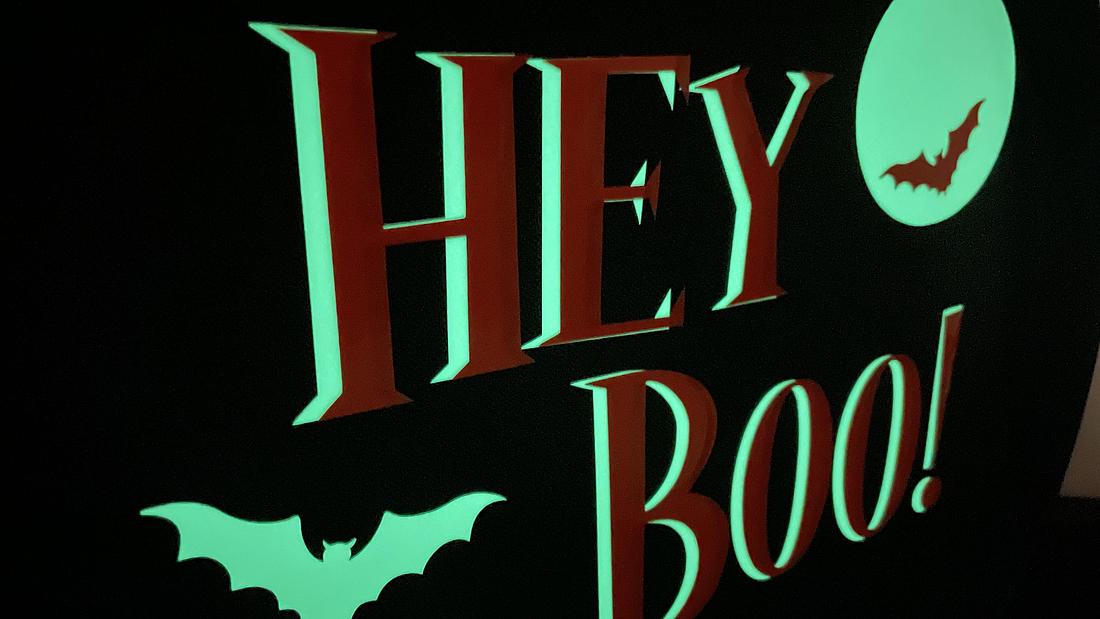

ORACAL 851 + ORALUX 9300 Halloween Wood Sign![]() ORACAL 851 + ORALUX 9300 Halloween Glasses

ORACAL 851 + ORALUX 9300 Halloween Glasses![]() ORACAL Glass Tumblers

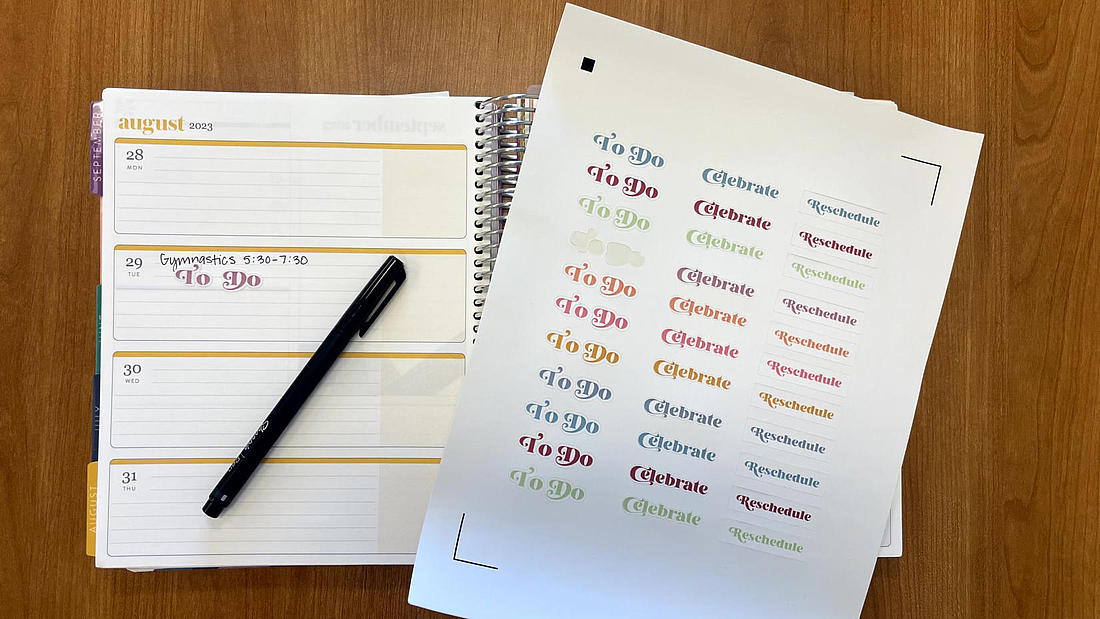

ORACAL Glass Tumblers![]() ORAJET 1917 Planner Stickers

ORAJET 1917 Planner Stickers![]() ORACAL 351 Wedding Hangers

ORACAL 351 Wedding Hangers![]() ORACAL 631 Homeschool Door Hanger

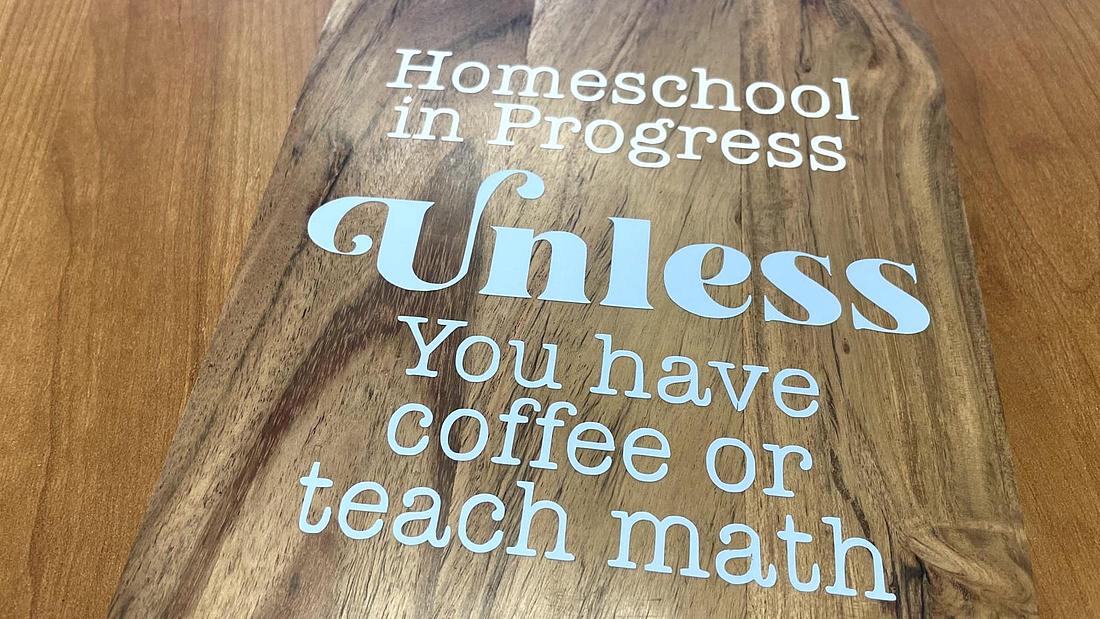

ORACAL 631 Homeschool Door Hanger![]() ORACAL 651 Flower Pots

ORACAL 651 Flower Pots![]() Acrylic Keychains Featuring ORACAL® 651™ + ORACAL® 631

Acrylic Keychains Featuring ORACAL® 651™ + ORACAL® 631![]() ORACAL 631 Classroom Door Hanger

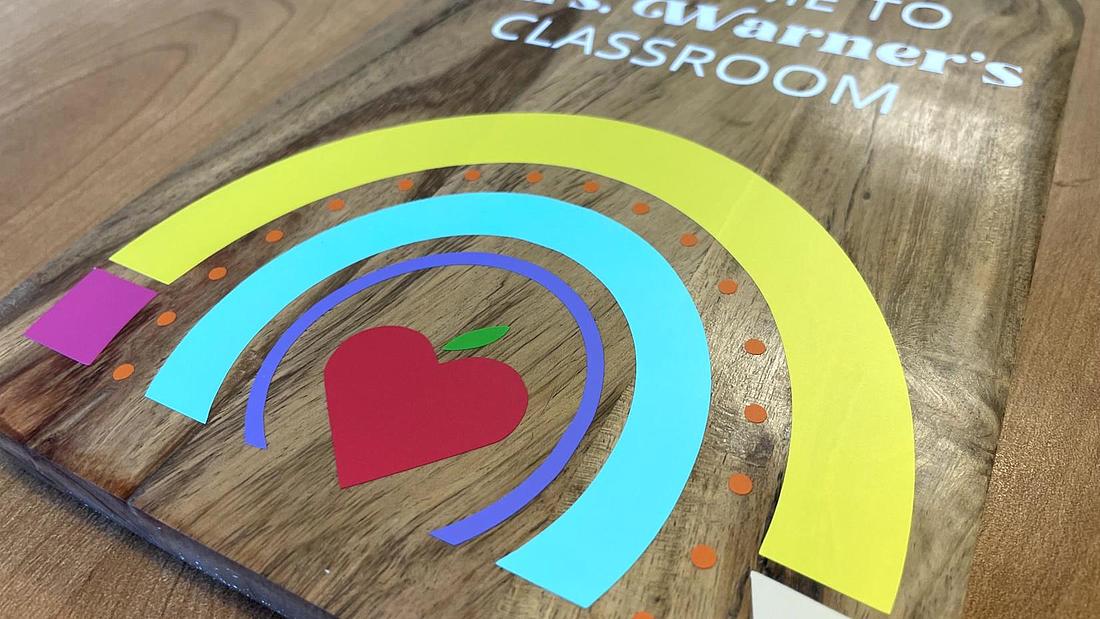

ORACAL 631 Classroom Door Hanger![]() ORACAL 651 Gold Metallic Organization Trays

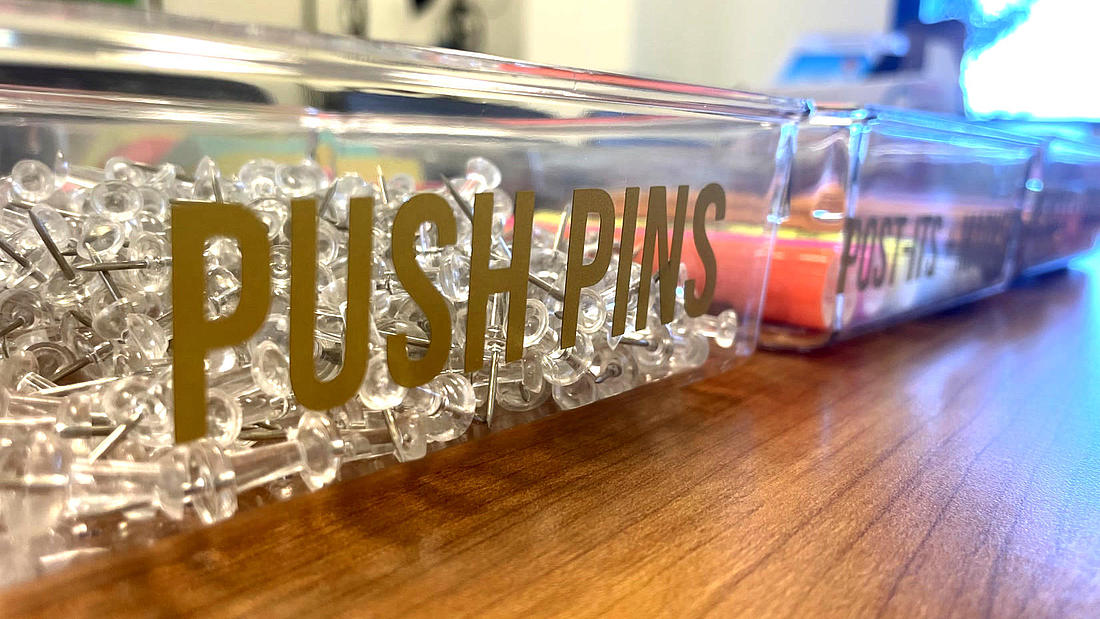

ORACAL 651 Gold Metallic Organization Trays![]() ORACAL 951 Water Bottles

ORACAL 951 Water Bottles![]() NEW COLOR ALERT! ORACAL 851, 977 Electric Orange

NEW COLOR ALERT! ORACAL 851, 977 Electric Orange![]() New ORACAL 851 Colors Now Available!

New ORACAL 851 Colors Now Available!![]() Football Door Hanger with ORACAL 851

Football Door Hanger with ORACAL 851![]() You Grow Girl Flower Pot Featuring ORACAL 851

You Grow Girl Flower Pot Featuring ORACAL 851![]() Merica Wine Glasses Featuring ORACAL 351

Merica Wine Glasses Featuring ORACAL 351![]() How to Layer with Ease using ORATAPE MT80P

How to Layer with Ease using ORATAPE MT80P![]() Custom Clear Backpack with ORACAL® 651™

Custom Clear Backpack with ORACAL® 651™![]() Custom Pencil Bag with ORACAL® 651™

Custom Pencil Bag with ORACAL® 651™![]() Custom Cooler Monogram Featuring ORACAL® 651™

Custom Cooler Monogram Featuring ORACAL® 651™![]() Mermaid Car Decal Featuring ORACAL® 651™ + ORACAL® 851

Mermaid Car Decal Featuring ORACAL® 651™ + ORACAL® 851![]() NEW YEAR RESOLUTION: Drink Less Caffeine Featuring ORACAL® 651™

NEW YEAR RESOLUTION: Drink Less Caffeine Featuring ORACAL® 651™![]() Custom Sand Buckets Featuring ORACAL® 641 + ORACAL® 851

Custom Sand Buckets Featuring ORACAL® 641 + ORACAL® 851![]() ORACAL 631 + 8300 Summer Door Hanger

ORACAL 631 + 8300 Summer Door Hanger![]() NEW YEAR RESOLUTION: Loose Weight Featuring ORACAL® 631

NEW YEAR RESOLUTION: Loose Weight Featuring ORACAL® 631![]() Pumpkins to Pumpkins: Customize your favorite platters with ORACAL® 631

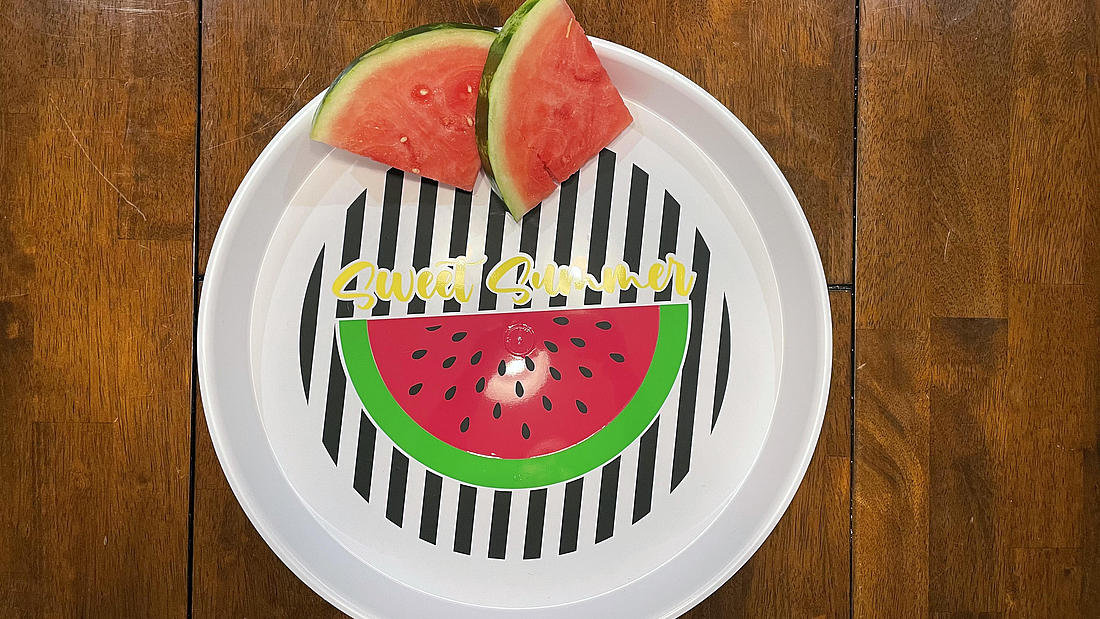

Pumpkins to Pumpkins: Customize your favorite platters with ORACAL® 631![]() ORACAL® 751 Summer Platter

ORACAL® 751 Summer Platter![]() Custom Water Bottles with ORACAL® 951

Custom Water Bottles with ORACAL® 951![]() Custom Golf Cart with ORACAL® 951

Custom Golf Cart with ORACAL® 951![]() I Told You So Coffee Mug Featuring ORACAL® 951

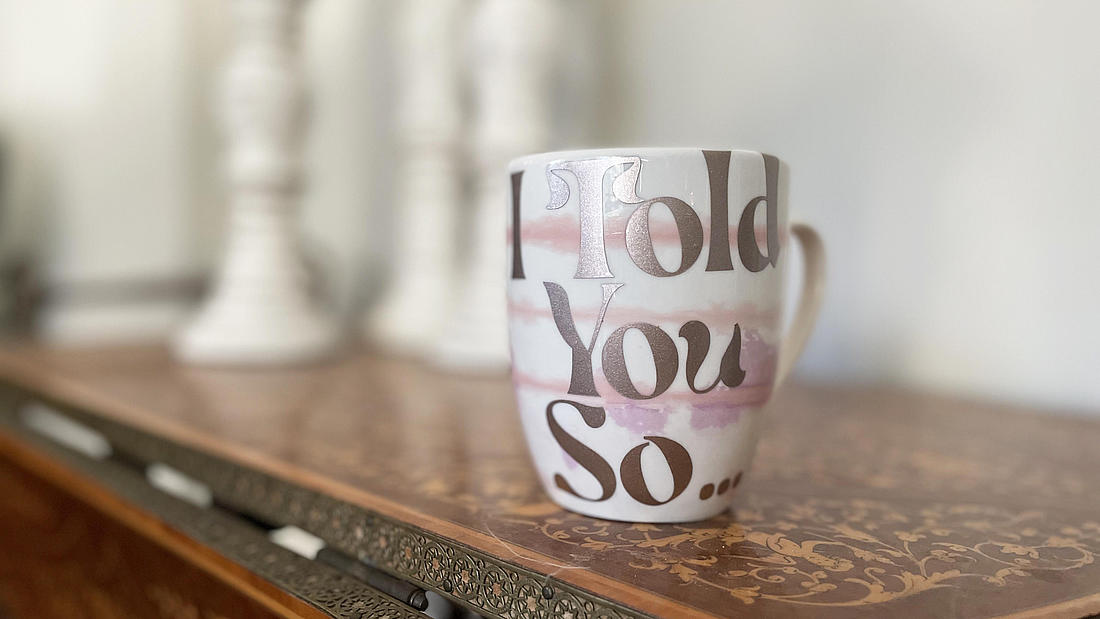

I Told You So Coffee Mug Featuring ORACAL® 951![]() Back to School Stickers with ORAJET® 1917

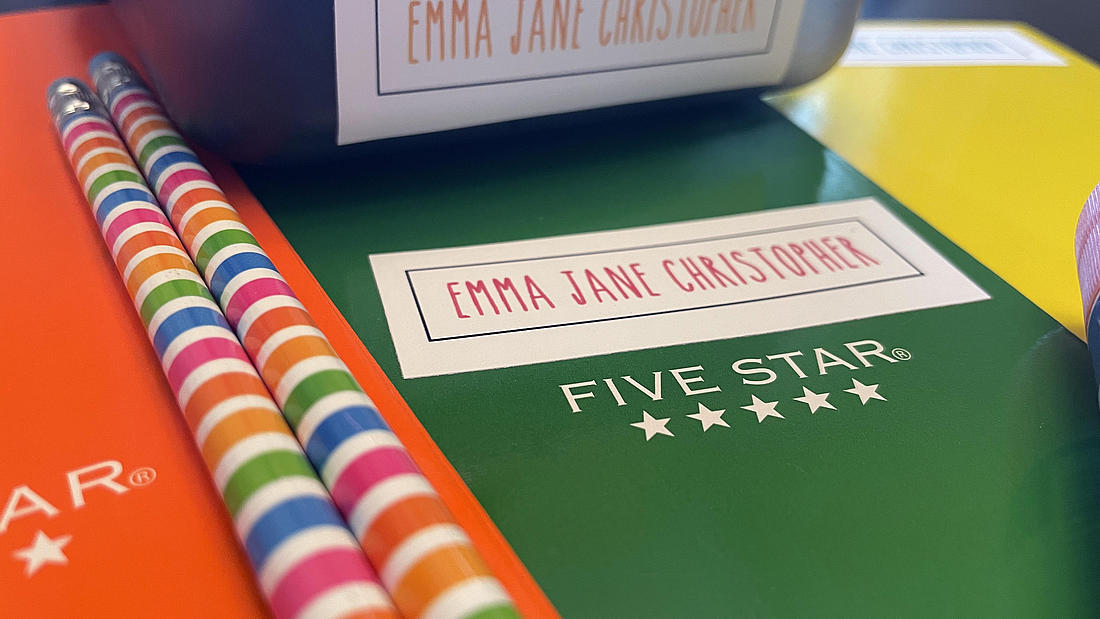

Back to School Stickers with ORAJET® 1917![]() Back to School Custom Labels Featuring ORAJET® 1917

Back to School Custom Labels Featuring ORAJET® 1917![]() Spring Cleaning and Organizing with ORAJET® 1917

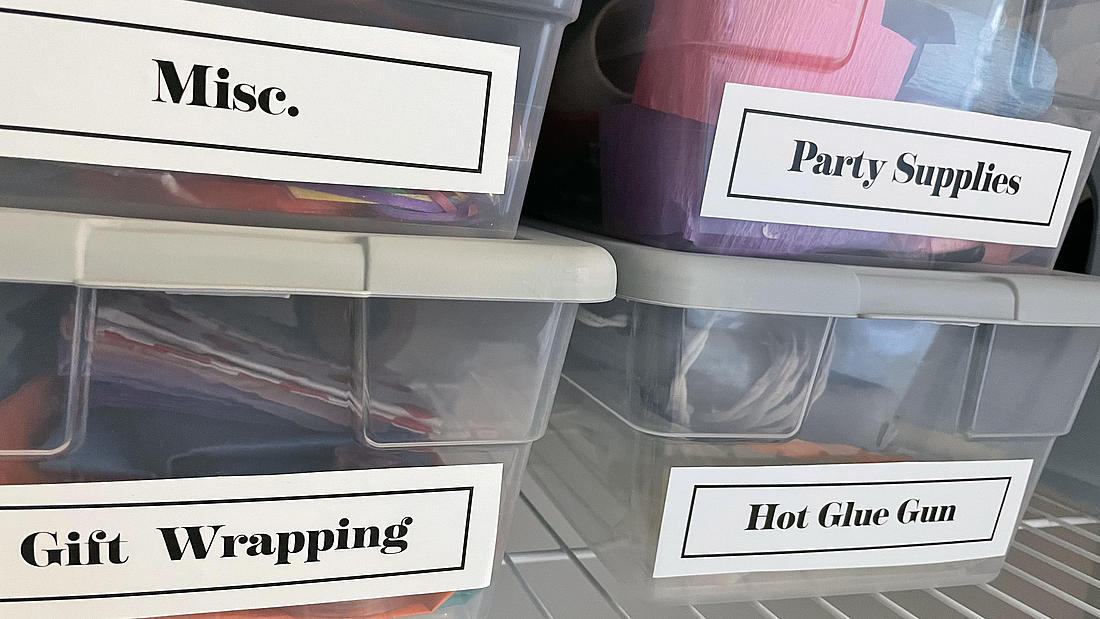

Spring Cleaning and Organizing with ORAJET® 1917![]() Seal it With a Kiss and ORAJET® 1917

Seal it With a Kiss and ORAJET® 1917![]() New Year Resolution: Get Organized with ORAJET® 1917

New Year Resolution: Get Organized with ORAJET® 1917![]() Custom Wedding Flutes Featuring ORACAL® 351

Custom Wedding Flutes Featuring ORACAL® 351![]() Glass Punch Container with ORACAL® 8810

Glass Punch Container with ORACAL® 8810![]() Cheer Mom Football Dad Tumblers with ORACAL® 8510

Cheer Mom Football Dad Tumblers with ORACAL® 8510![]() Customize Your Bike with ORACAL® 6510

Customize Your Bike with ORACAL® 6510![]() Give your patio door a face lift with ORACAL® 8300

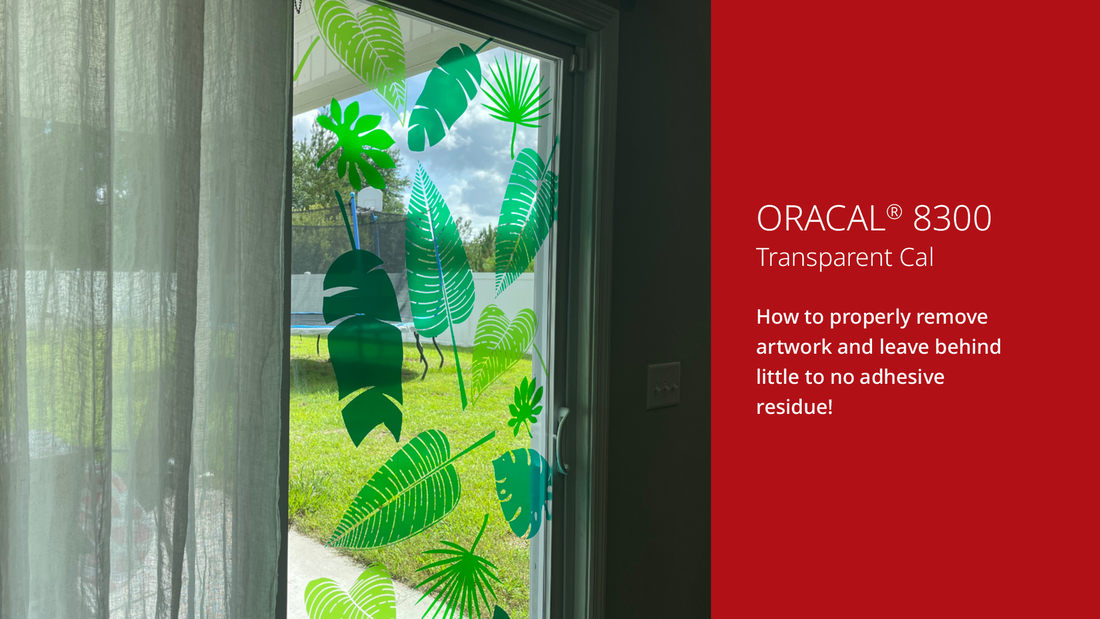

Give your patio door a face lift with ORACAL® 8300![]() How to Remove ORACAL® 8300

How to Remove ORACAL® 8300![]() Summer Watermelon Glasses Featuring ORACAL® 8300

Summer Watermelon Glasses Featuring ORACAL® 8300![]() ORACAL® 970RA Chalkboard Application

ORACAL® 970RA Chalkboard Application![]() Custom Bogg Bag Featuring ORACAL® 970RA

Custom Bogg Bag Featuring ORACAL® 970RA![]() Custom Treat Buckets with ORACAL® 9300 Glow In The Dark Vinyl

Custom Treat Buckets with ORACAL® 9300 Glow In The Dark Vinyl![]() Halloween Treat Bags with ORALUX® 9300

Halloween Treat Bags with ORALUX® 9300![]() Halloween Decor with ORALUX® 9300 + ORACAL® 851

Halloween Decor with ORALUX® 9300 + ORACAL® 851![]() Glow in the Drak Vinyl with ORALUX® 9300

Glow in the Drak Vinyl with ORALUX® 9300![]() NEW ORALITE V98 Pre-Striped Chevron

NEW ORALITE V98 Pre-Striped Chevron![]() Works When Wet Demo

Works When Wet Demo

Literature

![]() NEW 2023 Digital Inkjet Media Selection Guide

NEW 2023 Digital Inkjet Media Selection Guide![]() 2023 Multimedia Digital De Inyección De Tinta Guía De Selección

2023 Multimedia Digital De Inyección De Tinta Guía De Selección![]() 2023 Supports pour jet d’encre numérique Guide de sélection

2023 Supports pour jet d’encre numérique Guide de sélection![]() NEW 2023 ORAFOL Wrap Film Solutions

NEW 2023 ORAFOL Wrap Film Solutions![]() ORACAL® Color Chart

ORACAL® Color Chart![]() Craft Vinyl Selection Guide

Craft Vinyl Selection Guide![]() Vinilo Artesanal Guía de Selección

Vinilo Artesanal Guía de Selección![]() Vinyle d’art Guide de Sélection

Vinyle d’art Guide de Sélection![]() Plotter Films Product Selection Tool - Good, Better, Best Guide

Plotter Films Product Selection Tool - Good, Better, Best Guide![]() Digital Media & Laminates Product Selection Tool - Good, Better, Best guide

Digital Media & Laminates Product Selection Tool - Good, Better, Best guide![]() ORACAL® 970RA Color Chart

ORACAL® 970RA Color Chart![]() ORACAL® 751 Color Chart

ORACAL® 751 Color Chart![]() ORACAL® 651 Color Chart

ORACAL® 651 Color Chart![]() ORACAL® 631 Color Chart

ORACAL® 631 Color Chart![]() Glass Decoration Color Chart

Glass Decoration Color Chart![]() ORACAL® 8800 Color Chart

ORACAL® 8800 Color Chart![]() ORACAL® 8500 Color Chart

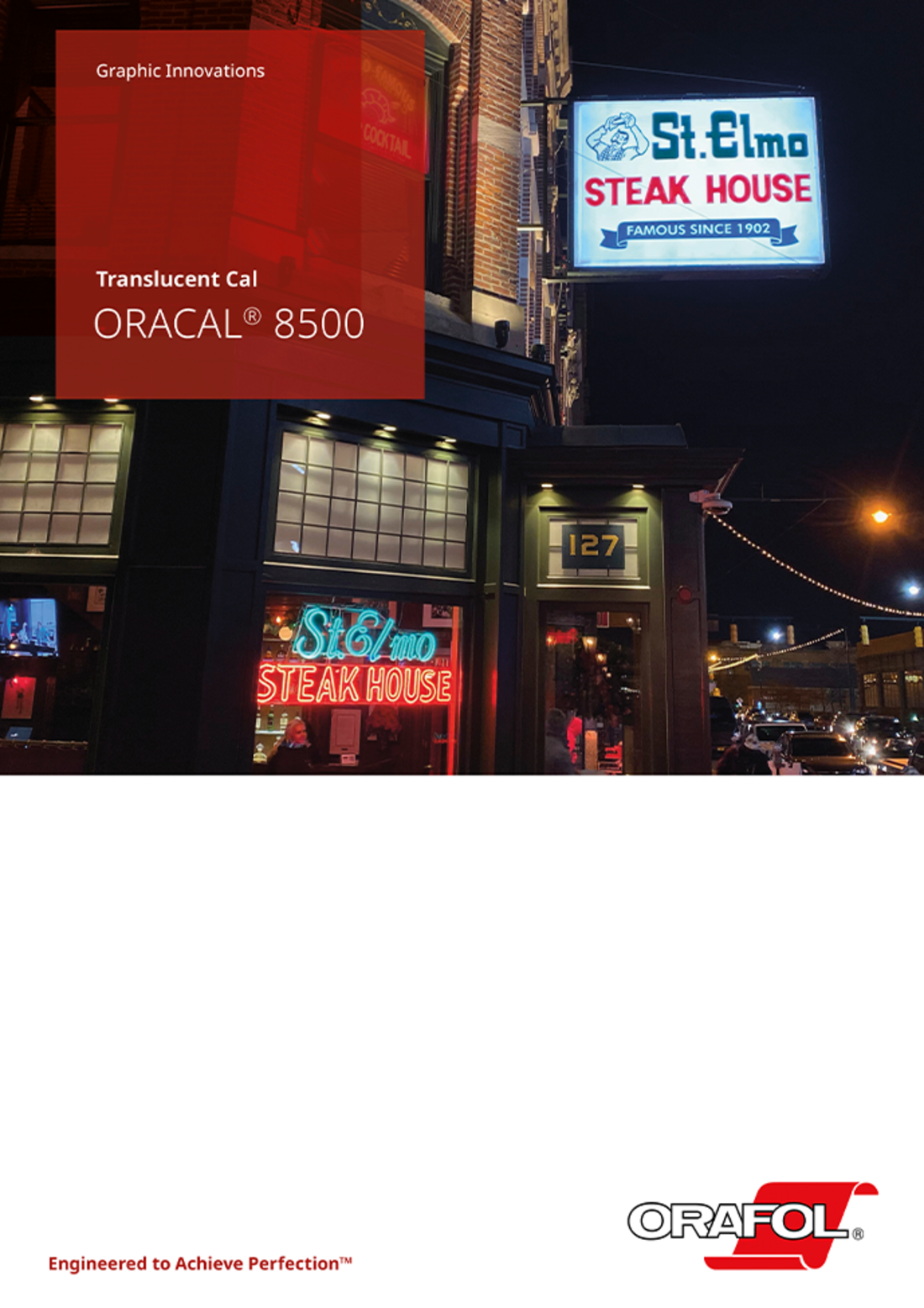

ORACAL® 8500 Color Chart![]() Color Cross Reference Guide - ORACAL® 8800 + 8500

Color Cross Reference Guide - ORACAL® 8800 + 8500![]() ORACAL® 851 Color Card

ORACAL® 851 Color Card![]() ORACAL® 751RA Color Card

ORACAL® 751RA Color Card![]() ORACAL® 651™ MATTE Color Card

ORACAL® 651™ MATTE Color Card![]() ORACAL® 641 Color Card

ORACAL® 641 Color Card![]() ORACAL® 651 Product Flyer

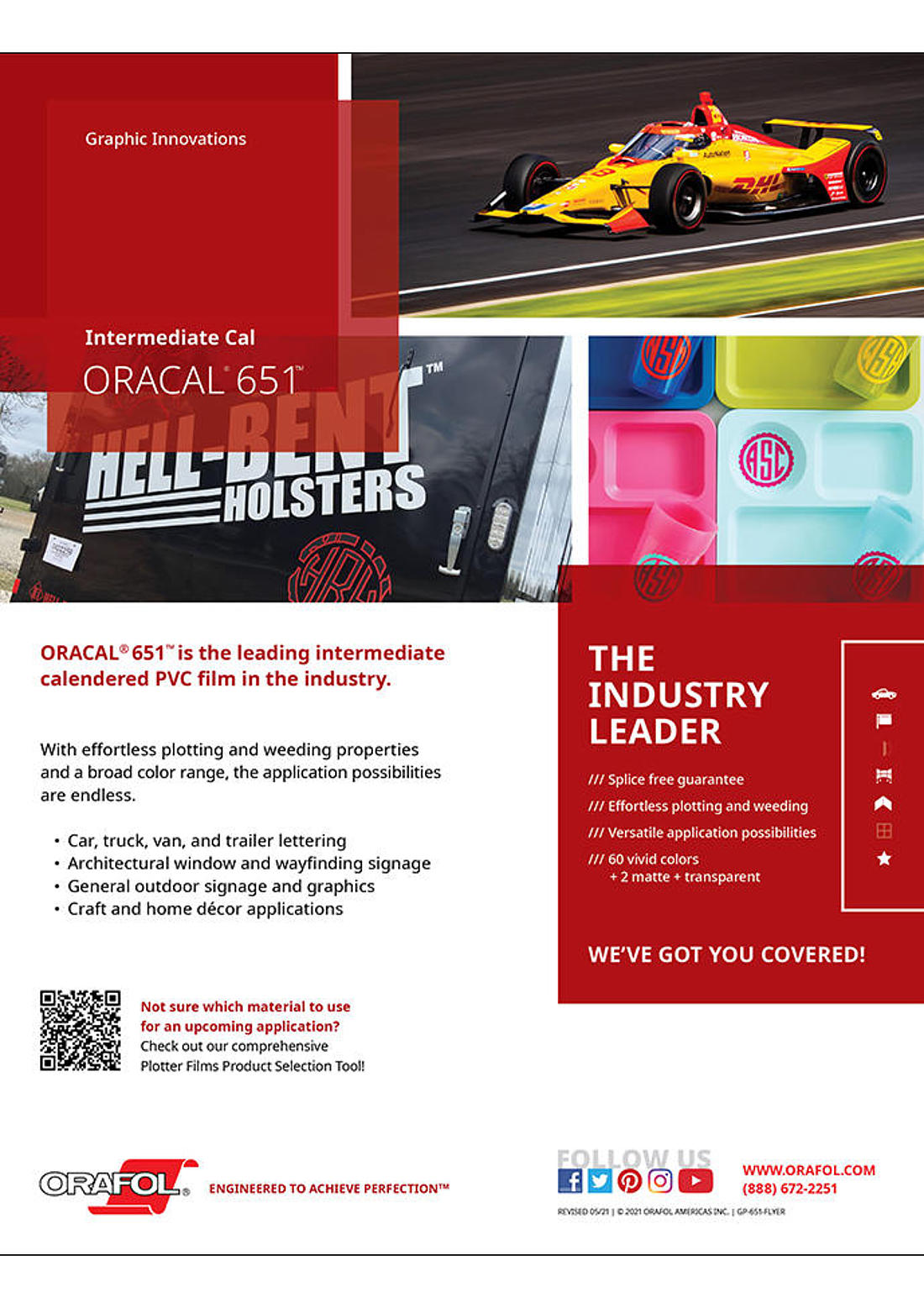

ORACAL® 651 Product Flyer![]() ORAJET Intermediate Calendered Digital Media

ORAJET Intermediate Calendered Digital Media![]() ORAJET Economy Calendered Digital Media

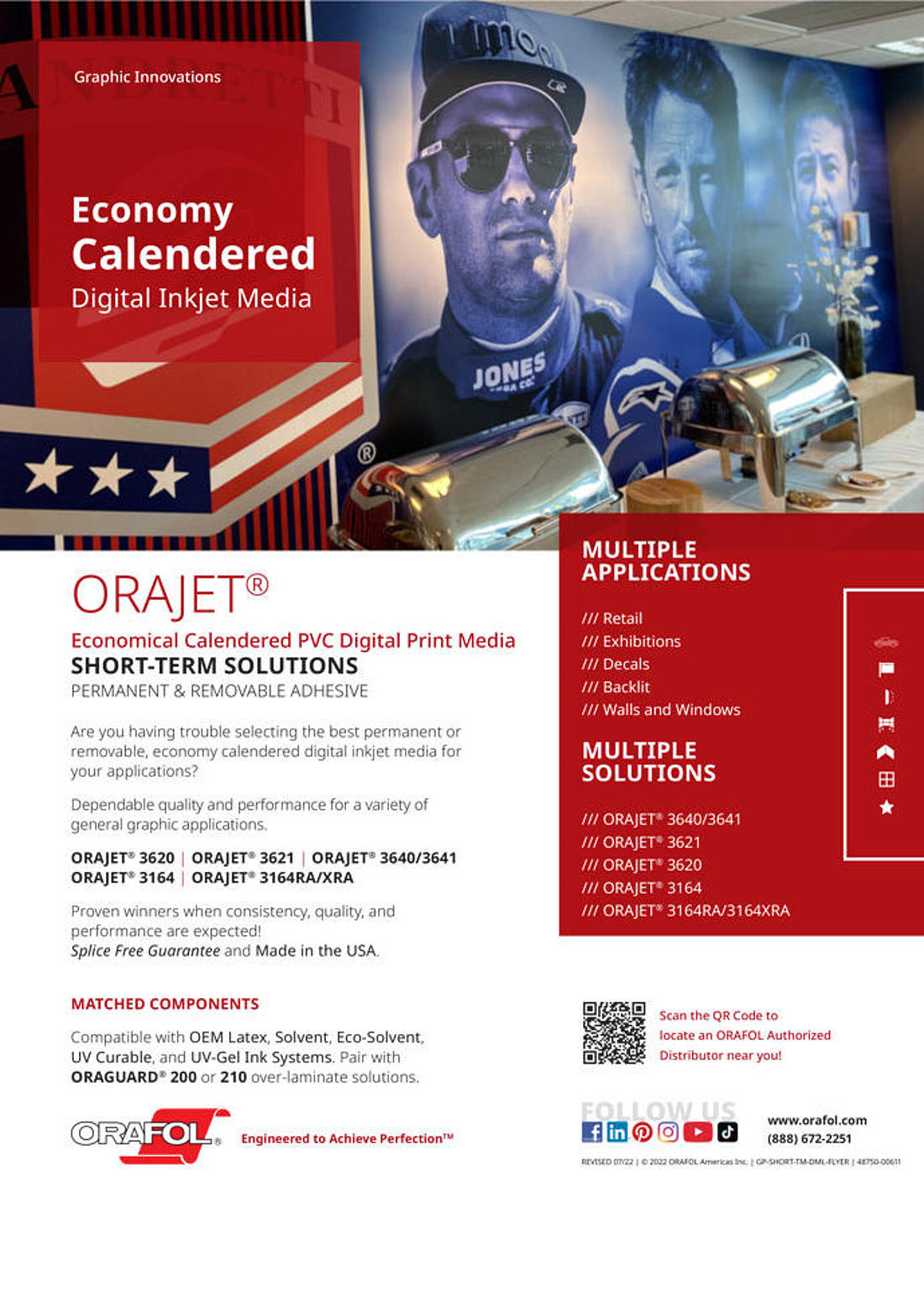

ORAJET Economy Calendered Digital Media![]() ORAJET 3740 & 3720 Product Flyer

ORAJET 3740 & 3720 Product Flyer![]() ORAJET 3740 y 3720 Libre de PVC A Corto Plazo Sustratos De Impresión Digital

ORAJET 3740 y 3720 Libre de PVC A Corto Plazo Sustratos De Impresión Digital![]() ORAJET Small Business Calendered Digital Media

ORAJET Small Business Calendered Digital Media![]() Pequeñas y Medianas Empresas Sustratos de Impresión Digital Calandrado

Pequeñas y Medianas Empresas Sustratos de Impresión Digital Calandrado![]() Graphic Innovations ORAJET® 3952F New Product Flyer

Graphic Innovations ORAJET® 3952F New Product Flyer![]() Graphic Innovations High-Tack Graphics Flyer

Graphic Innovations High-Tack Graphics Flyer![]() Graphic Innovations Wrap Glove Flyer

Graphic Innovations Wrap Glove Flyer![]() ORALITE® Reflective Applications Color Chart

ORALITE® Reflective Applications Color Chart![]() Graphic Innovations ORALITE® 5600RA New Product Flyer

Graphic Innovations ORALITE® 5600RA New Product Flyer![]() Reflective Solutions for Traffic Signs

Reflective Solutions for Traffic Signs![]() Solutions Réfléchissantes Pour Panneaux de Signalisation

Solutions Réfléchissantes Pour Panneaux de Signalisation![]() Señales de Tráfico

Señales de Tráfico![]() Reflective Solutions for Work Zones

Reflective Solutions for Work Zones![]() Zonas de trabajo

Zonas de trabajo![]() Reflective Solutions for Vehicle Conspicuity

Reflective Solutions for Vehicle Conspicuity![]() Visibilidad Vehicular

Visibilidad Vehicular![]() Reflective Solutions for Emergency Response Brochure

Reflective Solutions for Emergency Response Brochure![]() Reflective Solutions for Personal Safety Brochure

Reflective Solutions for Personal Safety Brochure![]() ORAFOL Traffic Sign Printer

ORAFOL Traffic Sign Printer![]() ORALITE 9900 Brilliant Grade Premium Brochure

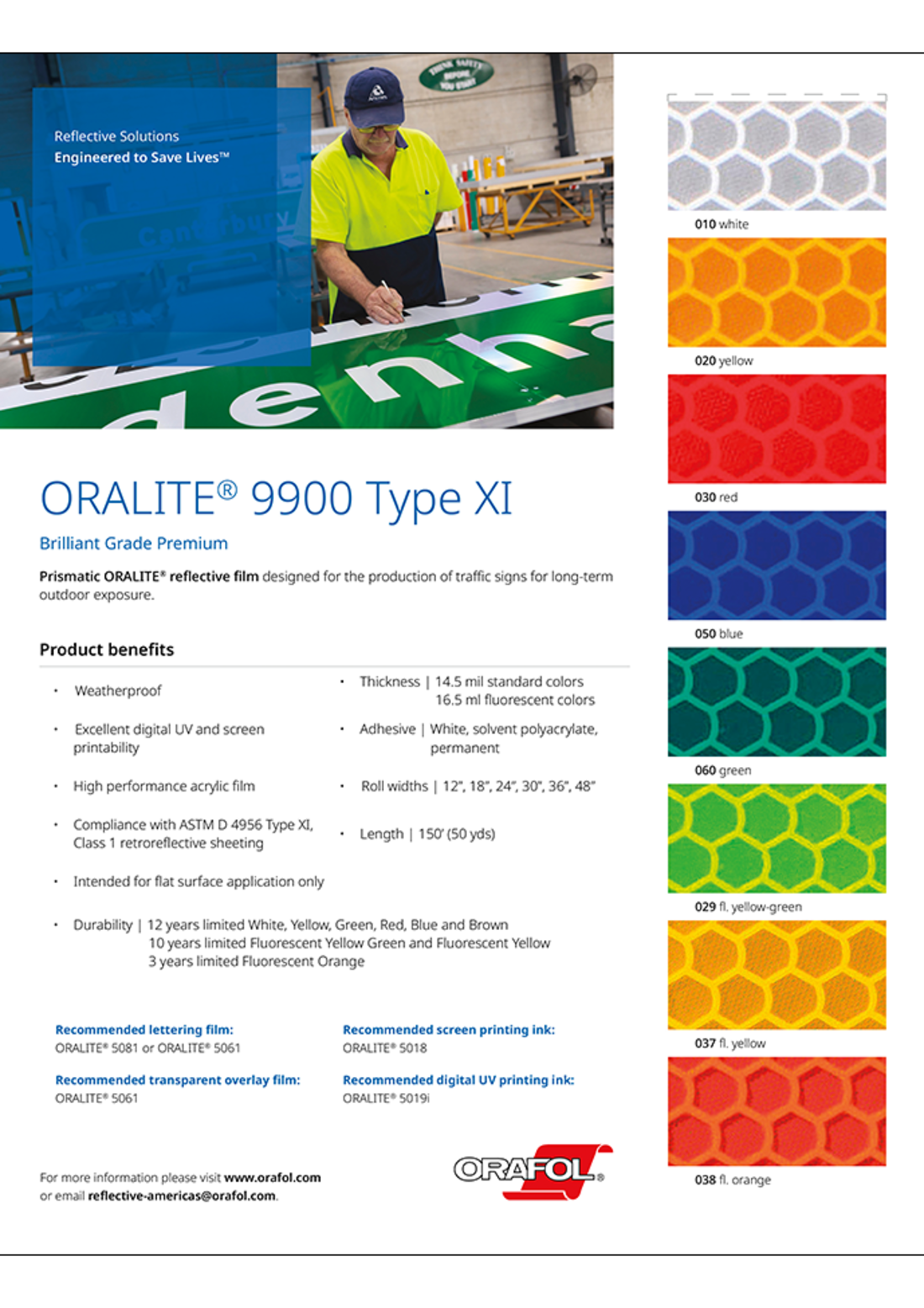

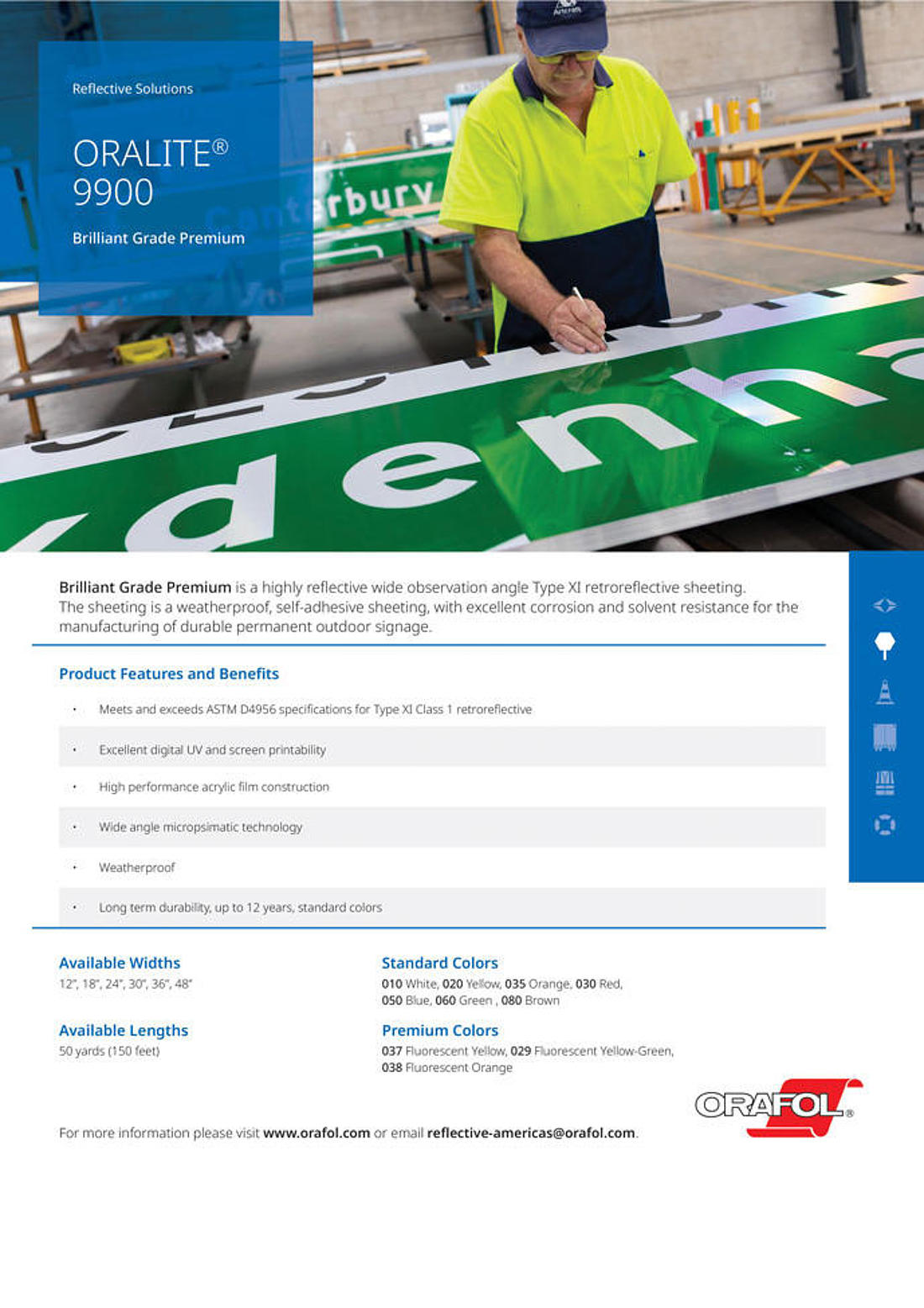

ORALITE 9900 Brilliant Grade Premium Brochure![]() ORALITE® Traffic Sign Sheeting Guide

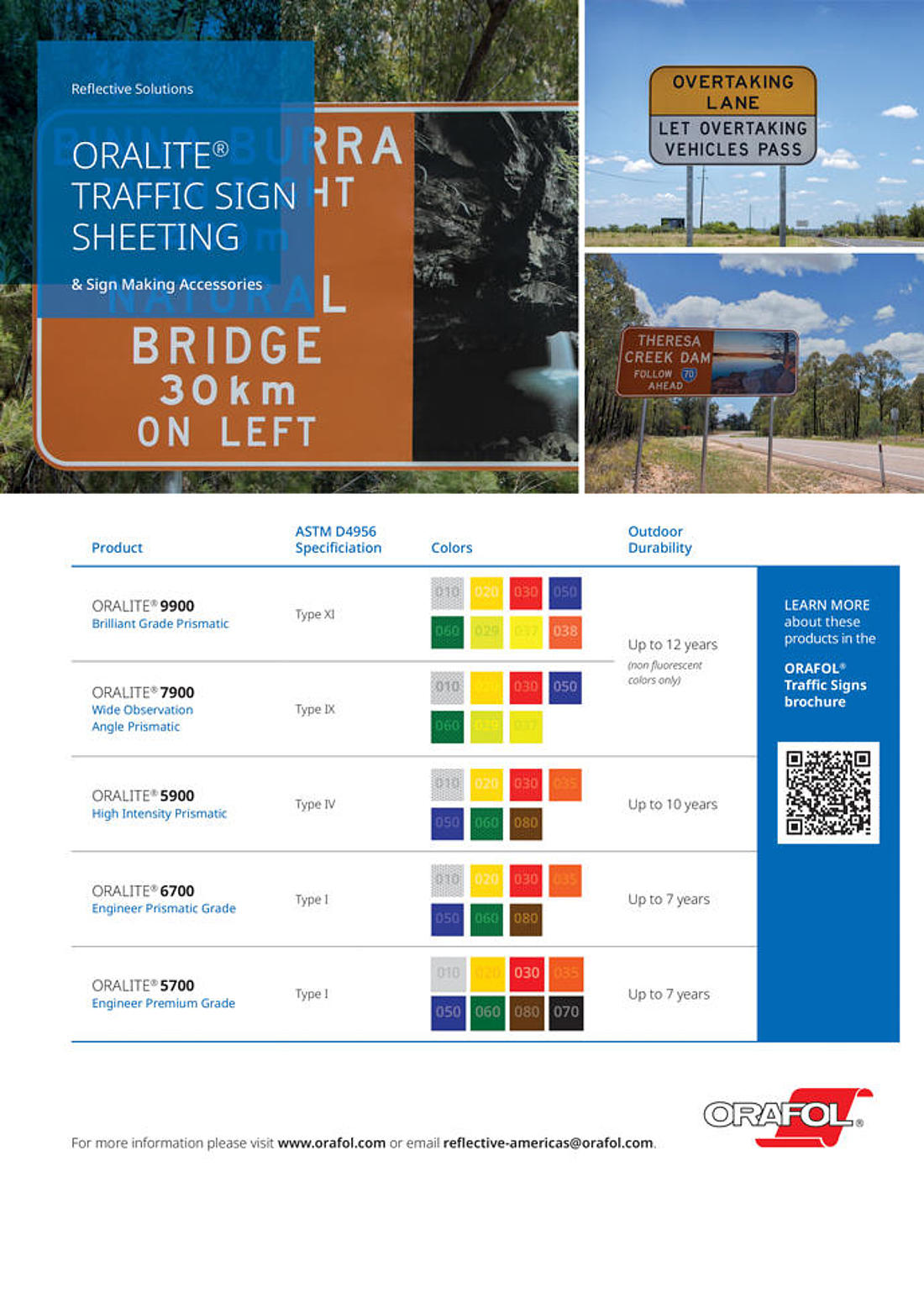

ORALITE® Traffic Sign Sheeting Guide![]() ORALITE® 9900 Color Card

ORALITE® 9900 Color Card![]() ORALITE® Brilliance™ Series Reflective Helmet Stickers, Sew On Patches, and Hot Dots

ORALITE® Brilliance™ Series Reflective Helmet Stickers, Sew On Patches, and Hot Dots![]() ORALITE® 7900 Color Card

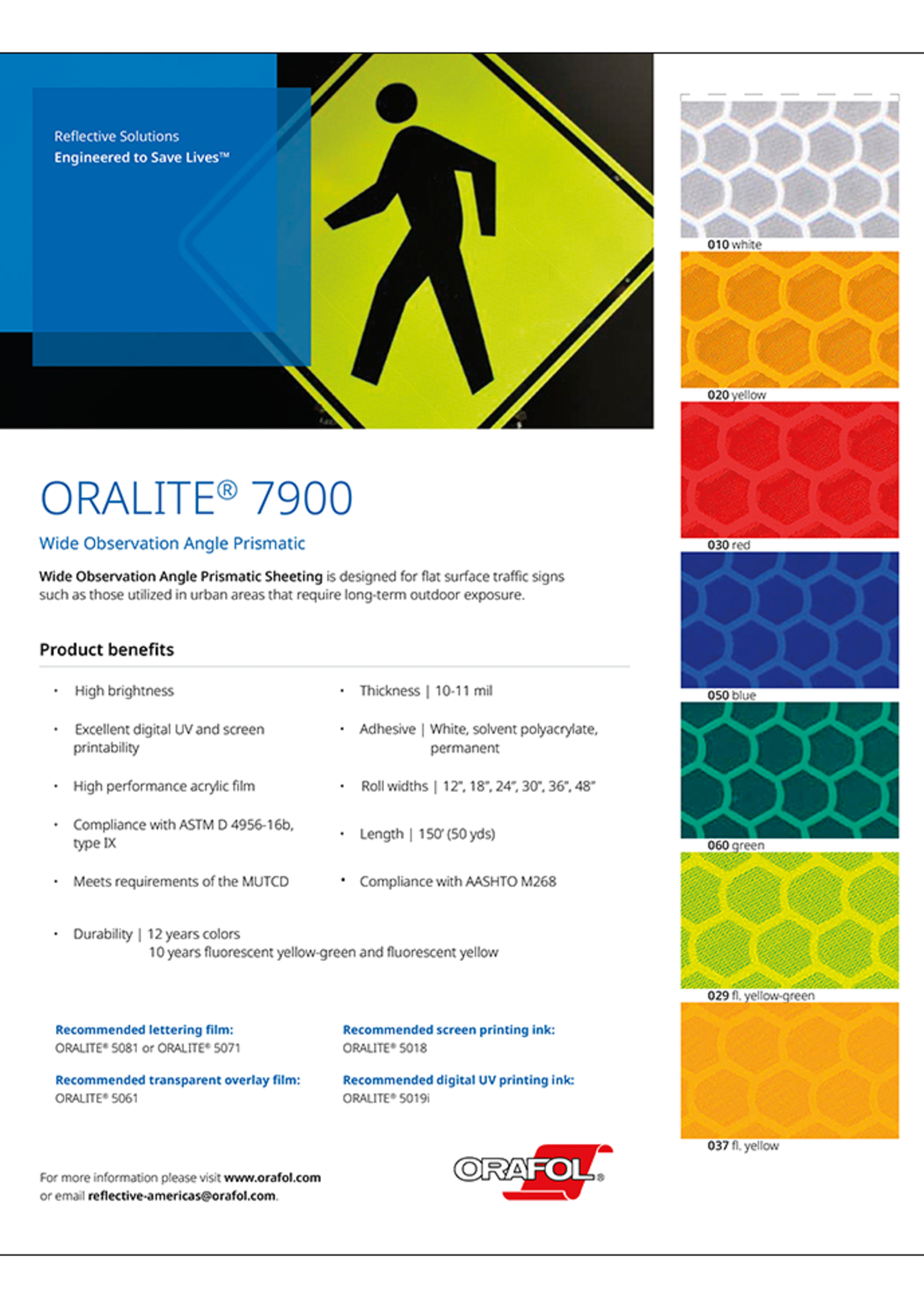

ORALITE® 7900 Color Card![]() ORALITE® 6700 Color Card

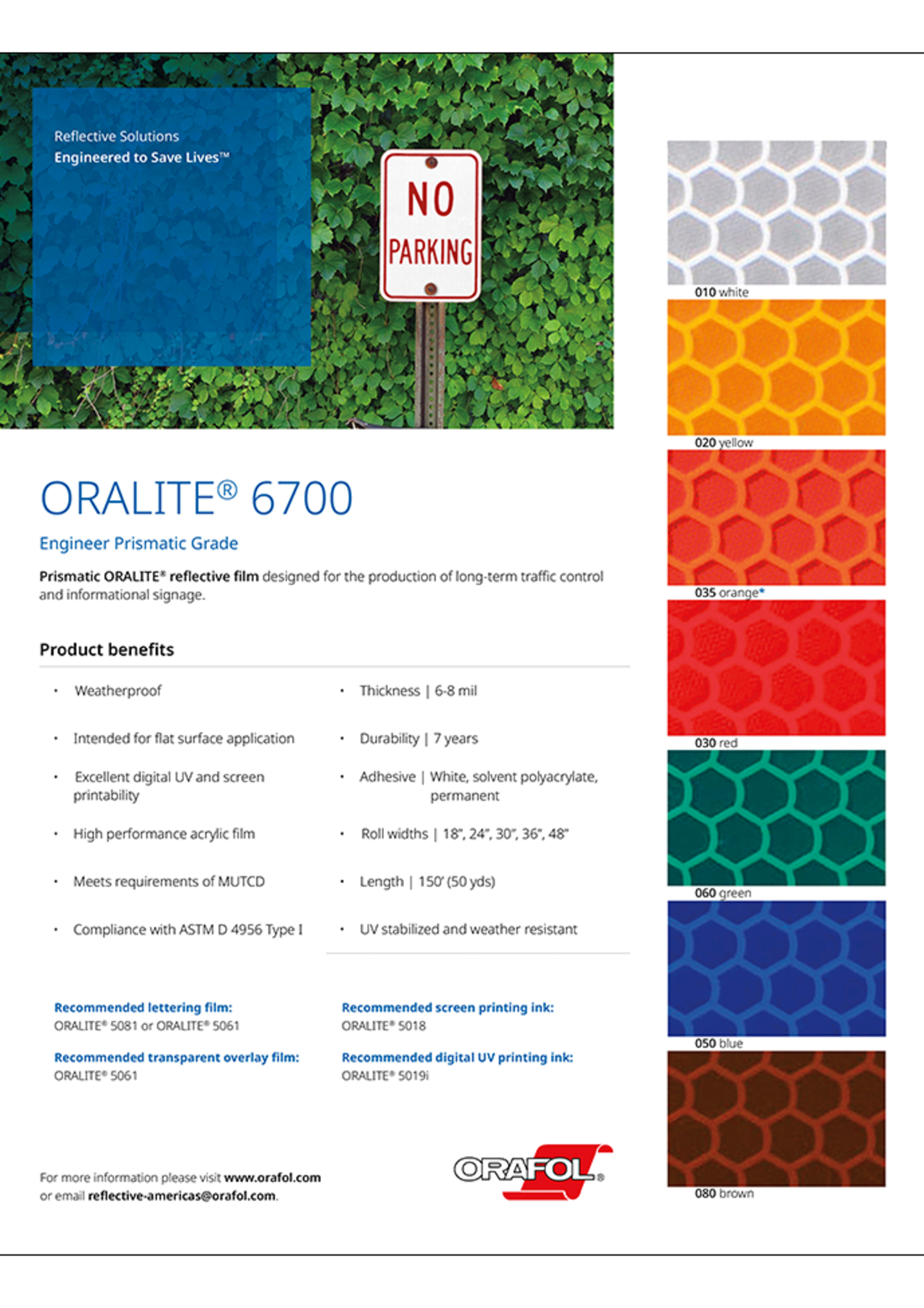

ORALITE® 6700 Color Card![]() ORALITE® 5900 Color Card

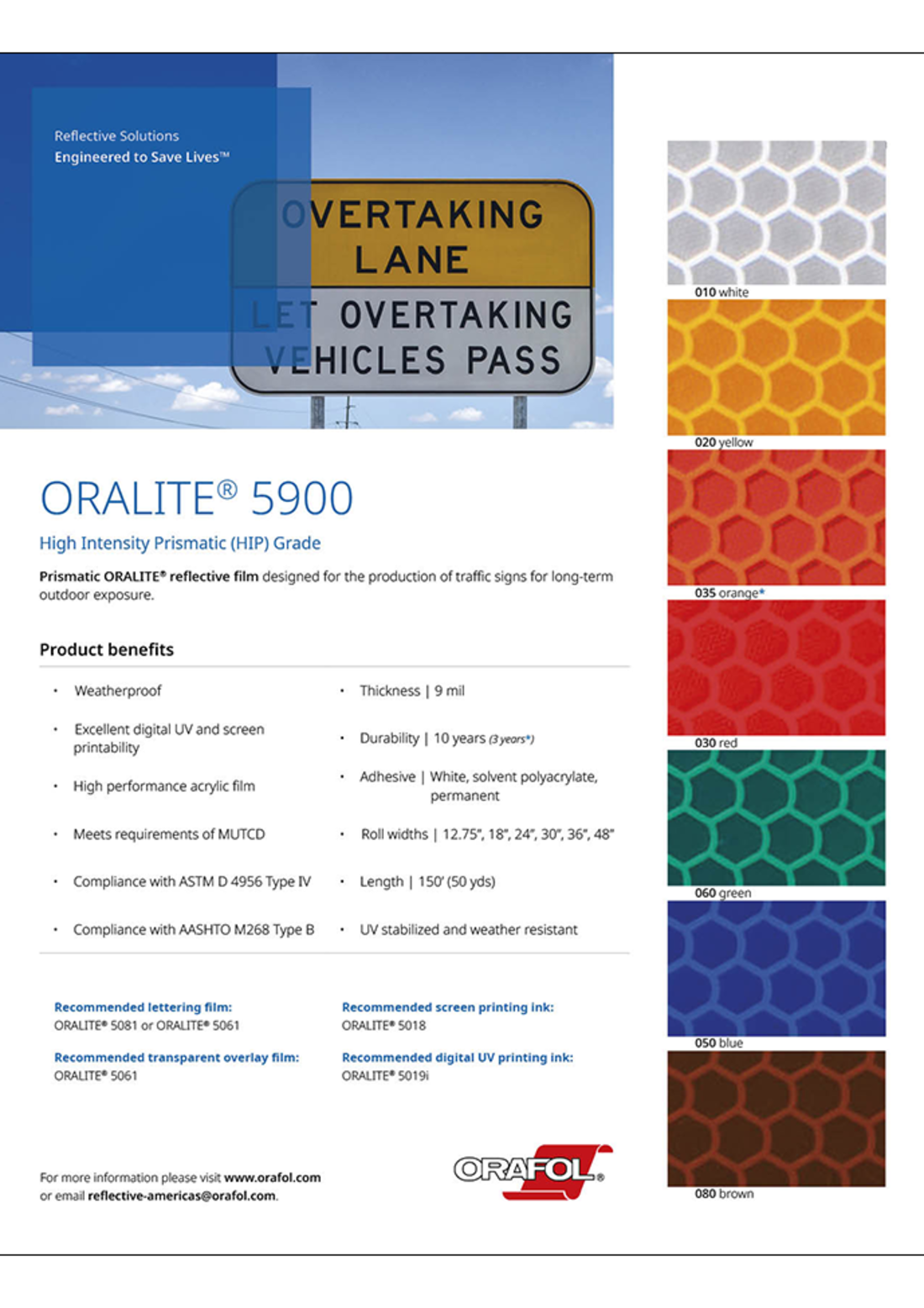

ORALITE® 5900 Color Card![]() ORALITE® 5934/5935

ORALITE® 5934/5935![]() ORALITE® 5930 Color Card

ORALITE® 5930 Color Card![]() ORALITE® 5600 + 5650RA Color Card

ORALITE® 5600 + 5650RA Color Card![]() ORALITE® 5061 Color Card

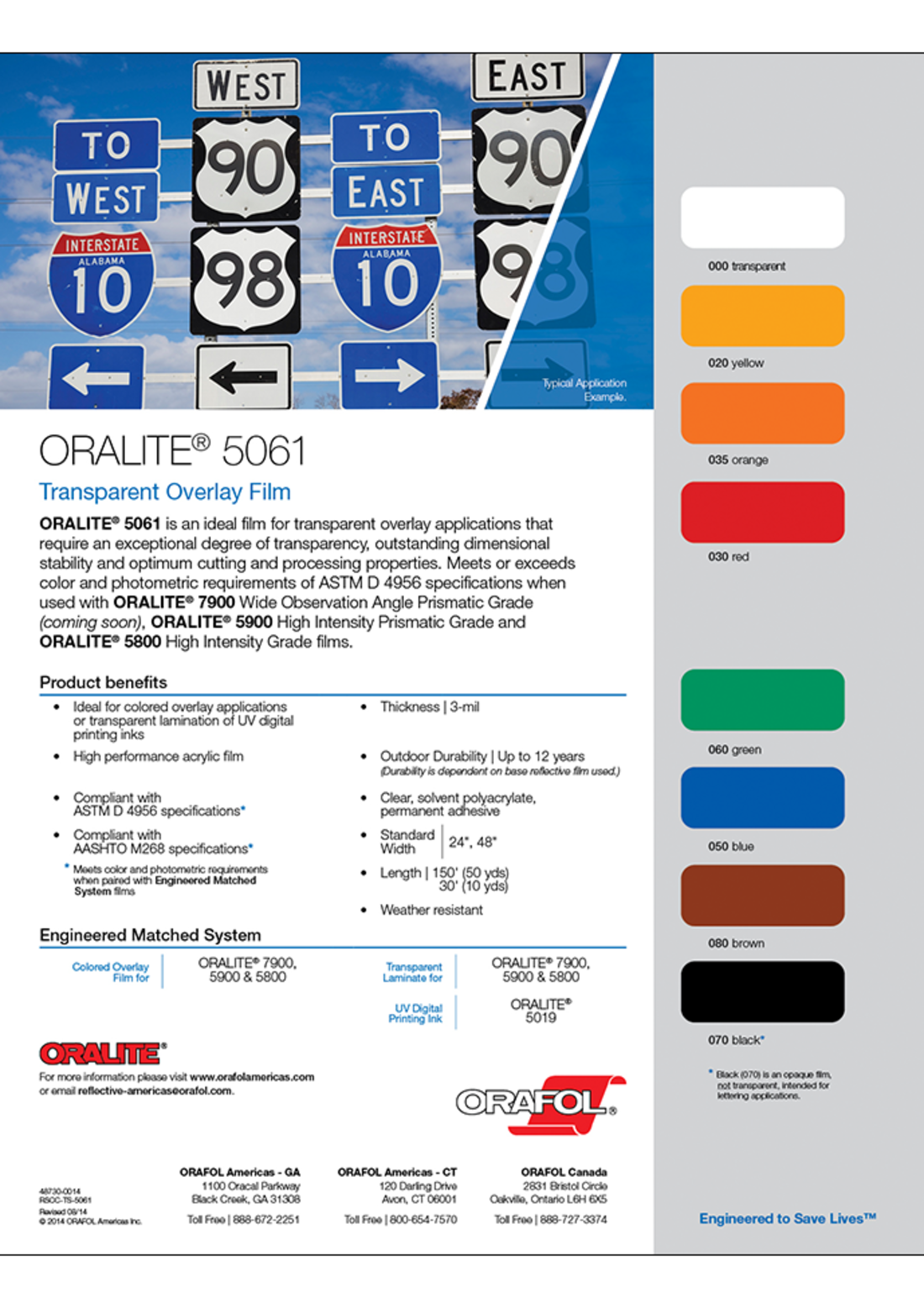

ORALITE® 5061 Color Card![]() ORALITE® V98 Color Card

ORALITE® V98 Color Card![]() ORALITE® V82 Color Card

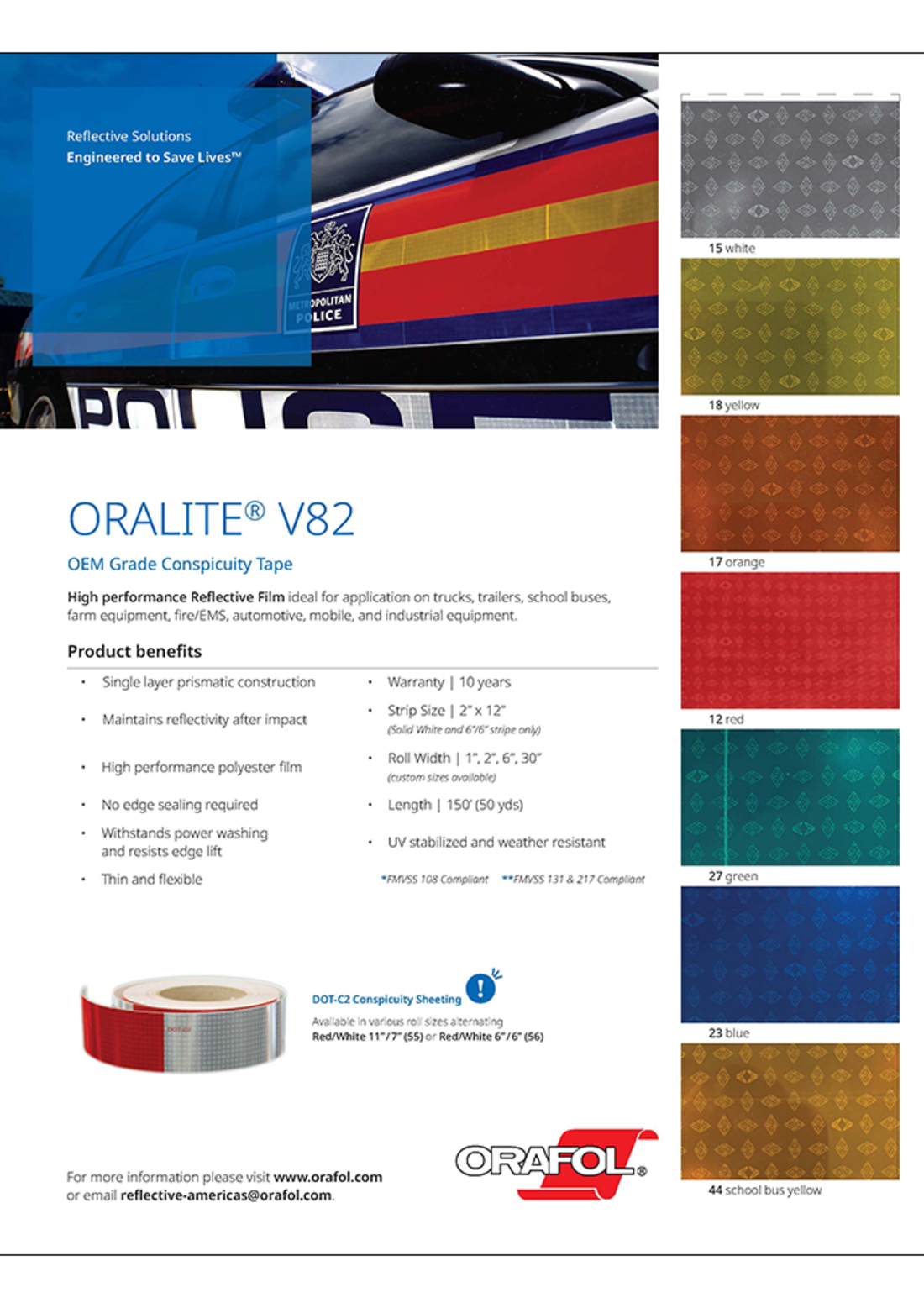

ORALITE® V82 Color Card![]() ORALITE 9900 Sell Sheet

ORALITE 9900 Sell Sheet![]() ORALITE® Brilliance® Series Sealed Prismatic Trims

ORALITE® Brilliance® Series Sealed Prismatic Trims![]() ORALITE® Prismatic Trims Works When Wet Flyer

ORALITE® Prismatic Trims Works When Wet Flyer![]() ORALITE® Marine Products

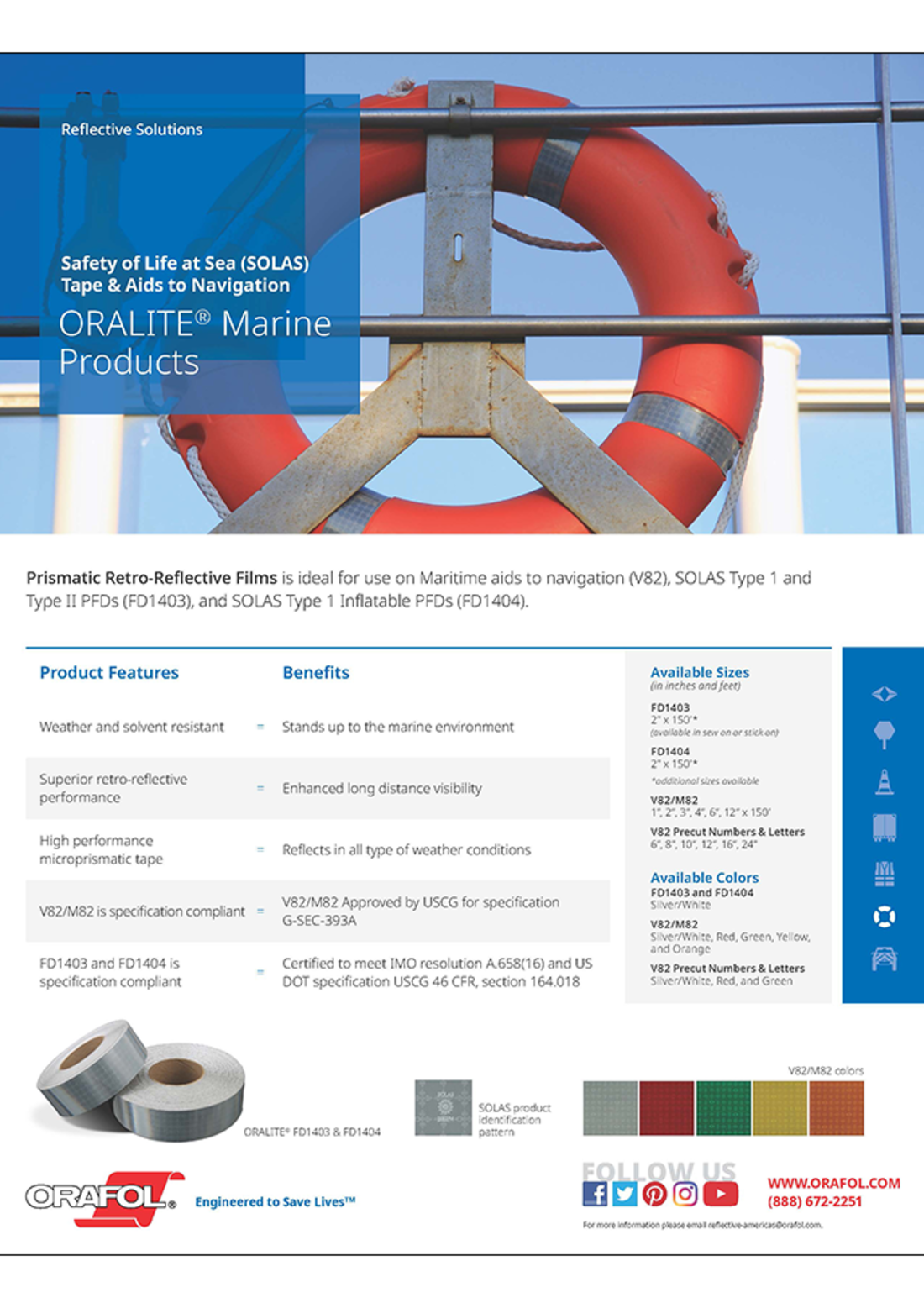

ORALITE® Marine Products![]() ORALITE® GP330 Product Flyer

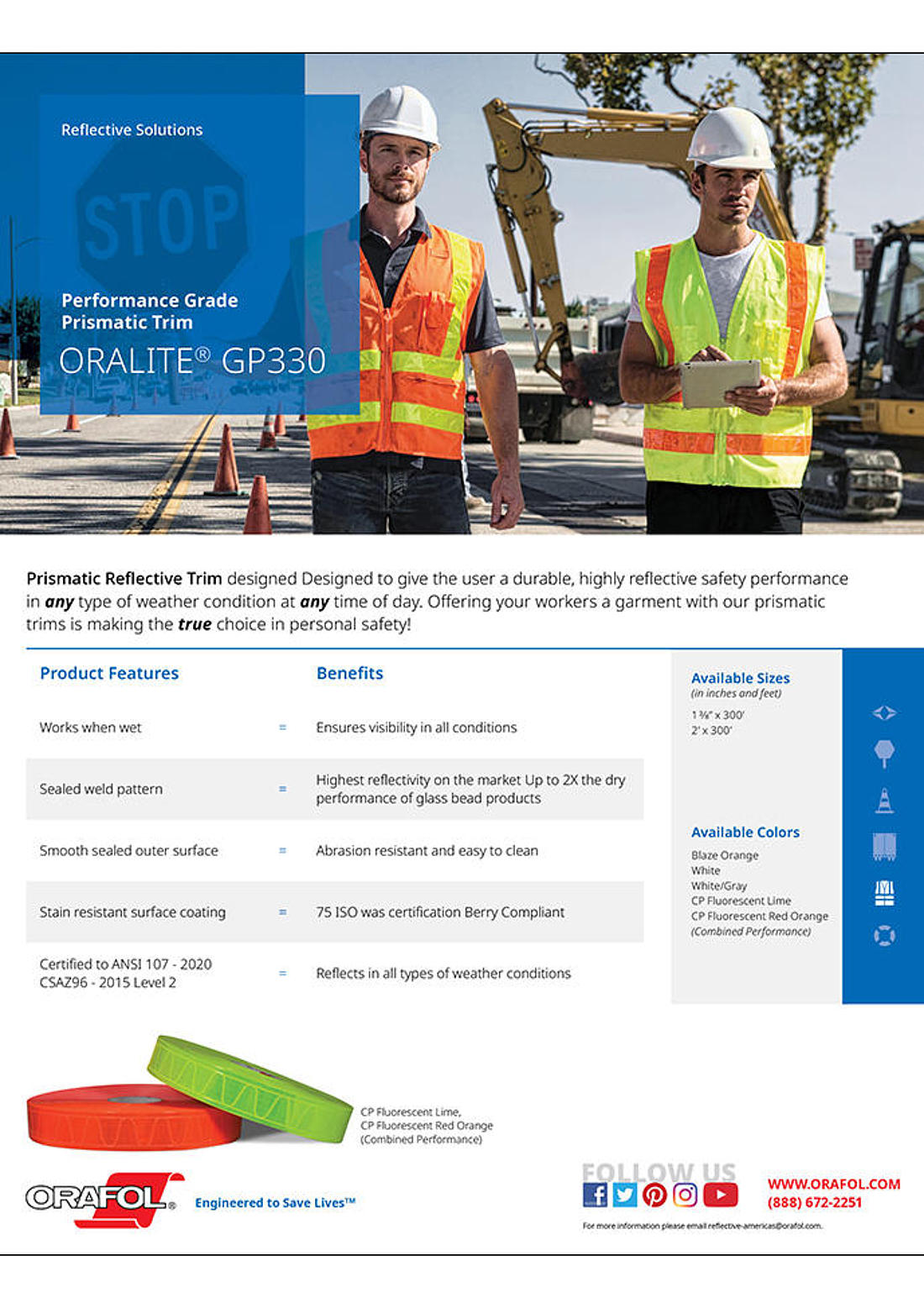

ORALITE® GP330 Product Flyer![]() ORALITE® GP440 Product Flyer

ORALITE® GP440 Product Flyer![]() ORAFILM® 1375/1377 High Performance Pure Acrylic Transfer Tape

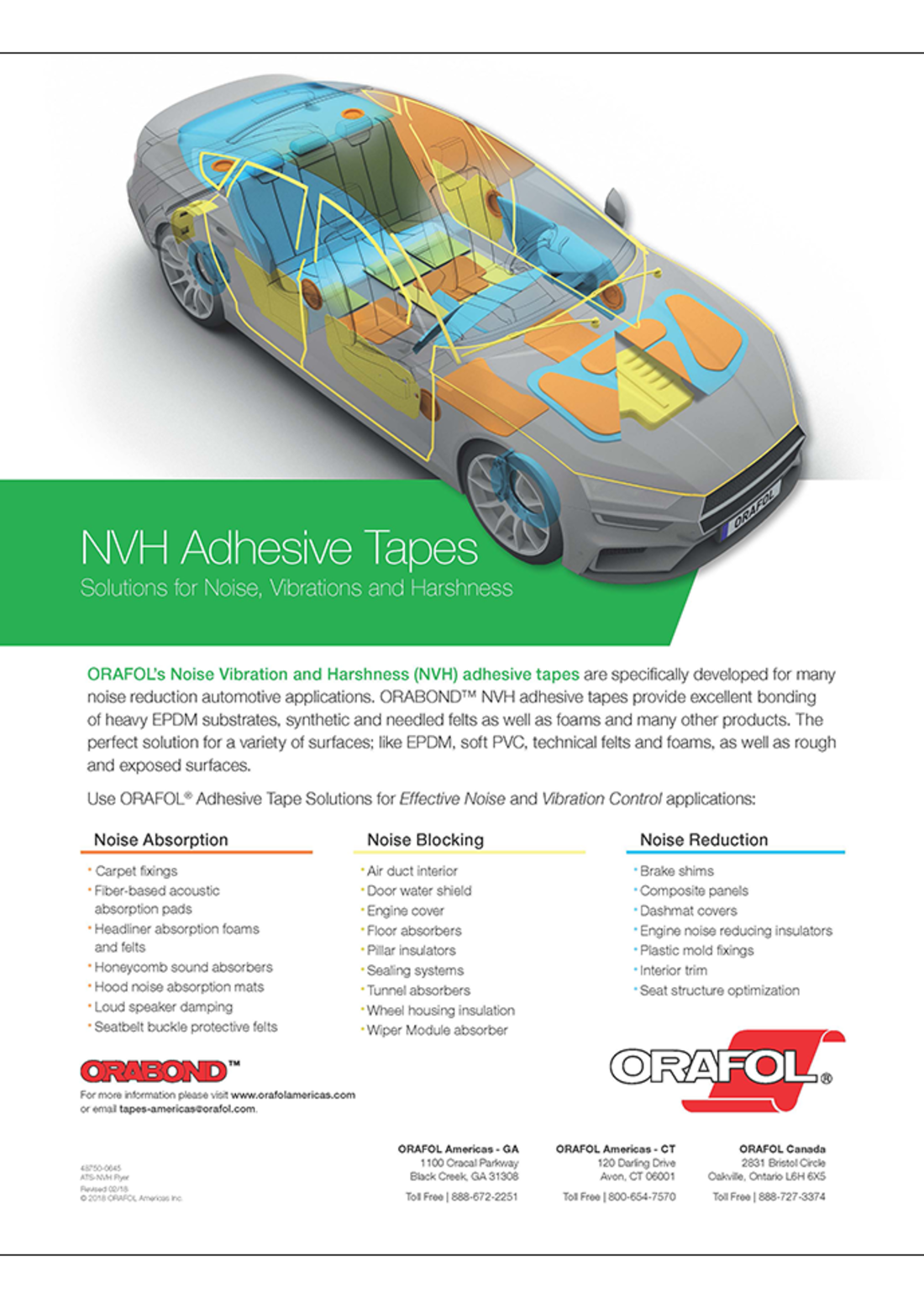

ORAFILM® 1375/1377 High Performance Pure Acrylic Transfer Tape![]() NVH Adhesive Tapes Flyer

NVH Adhesive Tapes Flyer![]() Ultra High Bond (UHB) Tapes Brochure

Ultra High Bond (UHB) Tapes Brochure![]() Rubans à adhérence très élevée

Rubans à adhérence très élevée![]() Cintas UHB con ultra alta fijación

Cintas UHB con ultra alta fijación![]() Screen Print Materials Brochure

Screen Print Materials Brochure![]() Adhesive Tape Systems Solutions for Sign and Display Applications

Adhesive Tape Systems Solutions for Sign and Display Applications![]() Solutions pour les applications relatives aux enseignes et aux présentoirs

Solutions pour les applications relatives aux enseignes et aux présentoirs![]() Soluciones para aplicación de señalización y letreros

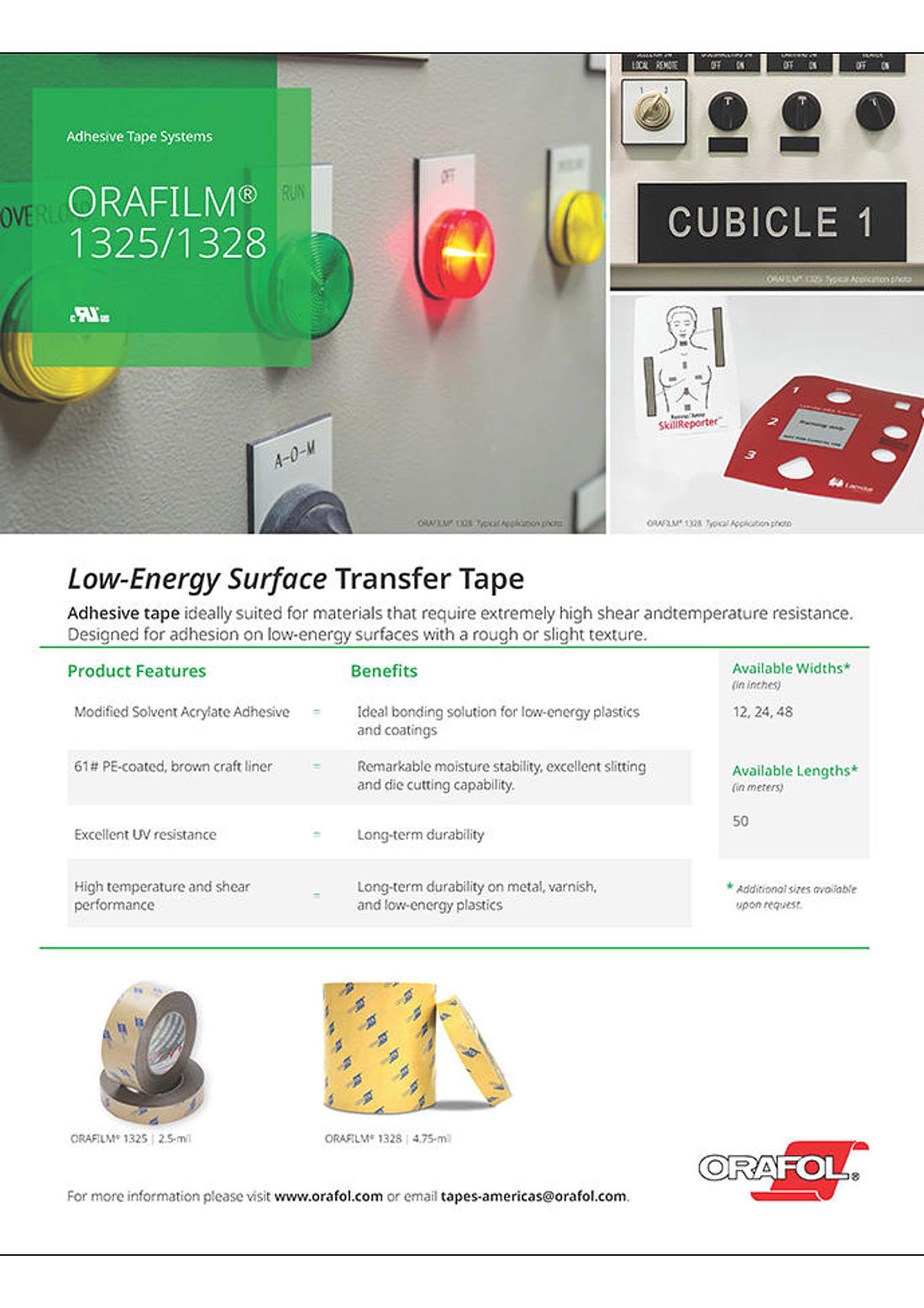

Soluciones para aplicación de señalización y letreros![]() ORAFILM® 1325/1328 Low-Energy Surface Transfer Tape

ORAFILM® 1325/1328 Low-Energy Surface Transfer Tape![]() Advanced Polymer Films

Advanced Polymer Films

Product Support Documents

Practical Information Flyers

- Production Procedures for Solvent & Eco-Solvent Digitally Printed Graphics

- Care and Maintenance of Vehicle Graphics

- Dealing with Fallout

- Processing & Handling Interior Wall Graphic Applications

- Processing & Handling ORAFOL® Floor Graphic Applications

- Processing & Handling Solid Color Vehicle Wraps

- Care & Maintenance Guidelines for ORACAL® 8000 Series Decorative Window Films

- ORACAL® 8800 PVC Cast Translucent Thermoforming Instructions

Product Bulletins

FAQs

Do you have a question that needs to be added to the list? Let us know!

ORAFOL Material Purchased on Amazon

ORAFOL material purchased on Amazon

Although it may appear that your order was “fulfilled by ORAFOL”, we assure you that it was not. All authentic ORAFOL materials sold on the Amazon platform are fulfilled by an Authorized ORAFOL Reseller. ORAFOL manufactures the material and sends larger rolls through its authorized distribution network, in which the Authorized ORAFOL Reseller purchases the material and converts the material into the various formats sold on the Amazon platform.

If you’ve experienced an issue with your purchase of ORAFOL materials on the Amazon platform, please contact the Authorized ORAFOL Reseller to submit a complaint concerning your order. If you’re having a difficult time identifying the Authorized ORAFOL Reseller that fulfilled your order, please try one of the following:

- “View Order Details” to contact the seller or initiate a “Return” through Amazon

- From the Menu, Select “Orders”

- Scroll to “Order info”

- Select “View order details”

- Copy your Order#

- Select “Delivered”

- Scroll down to “Sold by” and select the Seller, and click on “Ask a question” or review Return policy

The easiest route is to initiate a “Return”

- From Menu, Select ‘Orders”

- Locate and select the specific order from the list of recent purchases

- Under “Need help with your item?”

- Select “Return or replace items”

- Under “Why are you returning this?”

- Select “Missing or broken parts” or “Wrong item was sent”

- Select “Continue” to proceed with the return process

- Additionally, under “How’s your item?”

- Select “Leave seller feedback”

- Let other shoppers know that you’ve experienced an issue with your order

General Product Knowledge

Is “ORACAL” and “ORAFOL” the same thing?

Yes, ORAFOL is the name of ORAFOL Americas, Inc., a subsidiary of the ORAFOL Group. ORACAL® is a sub-brand of ORAFOL, and our Graphic Marking Films product line. ORAFOL has several sub-brands, including the following:

- ORAJET® - ORAFOL’s Digital Inkjet Media product line

- ORAGUARD® - ORAFOL’s Laminating Films product line

- ORALITE® - ORAFOL’s Reflective Solutions product line

- ORALUX® - ORAFOL's Photoluminescent product line

- ORAMASK® - ORAFOL's Stencil Film product line

- ORATAPE®, ORABOND®, and ORAFIX®, - ORAFOL’s Adhesive Tape Systems product line

Does ORAFOL use recycled materials?

Yes, all of ORAFOL’s boxes, cores, bags, and plugs are made from recyclable materials.

Cleaning & Maintaining Vinyl Graphics

Can I apply wax or polish to ORACAL® 970RA?

24 hours after installation is complete, apply a coat of ORACAL® Long-Lasting Seal. ORACAL® Long-Lasting Seal provides long-term protection for your car wrapping film, and should be applied once every 3-6 months for the life of the wrap.

- Gloss: This formula has been developed specifically for glossy car wrapping films and will provide an extremely smooth surface with a unique deep gloss. Contains PTFE.

- Matte/Satin: This formula has been developed specifically for matte car wrapping films and is water-free with a very high carnauba wax content.

Achieve the highest possible degree of protection with ORACAL® cleaning and care agents. Click here for recommended Post Car & Maintenance Guidelines for vehicle wraps.

I live in Southern California and have experienced occassions where vehicles I’ve wrapped form a rust-like appearance on the face of the graphic. What causes this condition?

While we can’t say for sure without proper samples and photographs of the actual vehicle, you’re probably seeing the result of “acid rain” or “fallout”, which we believe is caused by industrial pollutants that condense on the films surface in the form of dew when vehicles are left in the elements. Please see the Dealing with Fallout practical information flyer for more information.

What is the best cleaning solution to use for prepping substrates prior to application with ORAFOL films?

IPA (isopropyl alcohol) is generally recommended unless the substrate manufacturer states that there is an incompatability. Caution: Many cleaning agents can leave a residue that either prevent vinyl adhesion or attacks the vinyl adhesive, such as Windex® (and other glass or surface cleaners), Rapid Prep®, and degreasers.

What should I use if IPA (isopropyl alcohol) has been used to clean glass and there still seems to be a surface residue preventing vinyl adhesion?

We have found that Bon Ami® glass cleaner should remove any chemical residues left behind by other glass cleaners.

Vehicle/Fleet Applications

Does ORAFOL recommend any of its products for stainless steel tank applications?

Due to the wide variety of stainless steel types, gauges, applications, and aggressive cleaning regiments, ORAFOL Americas does not warranty its products when applied to stainless steel tanker trailers.

Which kind of ORAFOL films are suitable for making decals for automobiles?

ORAFOL offers a wide range of graphic marking films and digital media that are suitable for automotive decals. While you can obtain more specific application recommendations in the product section of our website, as a general rule we recommend the use of films with a solvent-based adhesive for automotive use. The solvent adhesive will last much longer when exposed to changing surface temperatures, chemicals and mild solvents. Also, our cast films tend to be more conformable and durable for demanding longer-term applications.

I have applied a decal using ORAJET® vinyl to my car window. How do I remove this when I am finished with it?

When the decal is no longer desired on your vehicle window, just simply apply heat to the decal using a heat gun. Hold the heat gun 6-9″ away from the decal dispersing the heat evenly over the surface of the decal for about 10-15 seconds. Peel up an edge of the decal and slowly pull back until the graphic is removed. Wipe away any residue left behind with Isopropyl Alcohol and a clean rag.

Is ORACAL® Series 8300 suitable for use on vehicle headlights and taillights?

No, ORAFOL assumes no liability for the possible damage that may be caused upon removal of its Series 8300 material from vehicle headlights and taillights. ORACAL® Series 8300 is designed for permanent, durable, internally illuminated signs and window graphics. ORACAL® 8300 is thermal print compatible and suitable for both wet and dry application. This material also offers impressive cutting and weeding properties.

Will ORACAL® Series 351 polyster chrome vinyl hold up on a vehicle body graphic?

ORACAL® Series 351 and 352 may be used to produce plotter cut decals or screen printed decals, and will last up to two years when properly applied and maintained on a vehicle. Since these are metallized films, these films are very rigid and offer no conformability to curved surfaces. ORACAL® 351 and 352 are not designed for vehicle wrapping.

How do I prepare the vehicle surface prior to applying a vehicle graphic?

Click here for complete Pre-Application & Application Guidelines

The surface of the vehicle must be free of dust, grease, or any other contamination that could keep the film from adhering properly. The vehicle should be washed and allowed to dry for 24 hours before wrap installation. Nooks and crevices are likely to trap moisture, and will result in poor adhesion. Wipe the vehicle with ORACAL® Pre-Wrap Surface Cleaner or isopropyl alcohol just before the installation to remove any soap residue or dust.

- Change cleaning rags often throughout the cleaning process for best results.

- Nooks, crevices, and under rubber seals should also be cleaned with one of these agents to promote proper adhesion into these areas.

- It is also possible to go over these areas with a heat gun to help drying.

Keep the vehicle in a controlled environment at the minimum temperate of 59°F during the drying time. The graphics must be stored in a controlled environment between 65°F and 75°F for a minimum of 24 hours prior to installation to promote an ideal application experience and performance.

Floor Graphics

Does ORAFOL make floor graphic films?

Yes. ORAJET® Series 1663 is specifically engineered for floor graphics printed with solvent inkjet printers. For durability and anti-skid properties we recommend combining this product with ORAGUARD® Series 250AS Laminating Film or ORAGUARD® Series 255AS(High Traffic Load)Laminating Film. Series 1663 can adhere to most smooth, sealed surfaces. We do not recommend applying this product to porous concrete, asphalt or masonry surfaces.

What floor graphic material does ORAFOL recommend for Social Distancing and other promotional floor graphic applications?

- Interior flooring surfaces that are smooth and sealed, consider ORAJET® 3621, 3169RA or 1663 digital print media and over-laminate with ORAGUARD® 250AS or 255AS Anti-Skid textured floor laminate.

- Exterior surfaces such as asphalt or concrete, consider ORAJET® 3105HT, 3951HT, or 3954 digital print media and over-laminate with ORAGUARD® 250AS or 255AS Anti-Skid textured floor laminate.

- Commercial Grade Carpet, consider ORAJET® 3165, 3651, or 3105HT digital print media and over-laminate with ORAGUARD® 250AS or 255AS Anti-Skid textured floor laminate.

Click here for complete Processing and Handling Floor Graphic Instructions

General Application

Why is ORAGUARD® 297GF recommended for laminating to ORAJET® Perforated Window Films?

ORAGUARD® 297GF is a thicker construction, making it more difficult to streak when applying the material with a squeegee. The thicker construction also holds up better in hot, humid environments and is less likely to collapse into the perforation holes in the print media.

What does ORAFOL recommend when performing a wet application with its products?

Wet applications are typically recommended for large surface applications of solvent-based adhesive products being applied to architectural glass and windows. We applications should only be done in ambient temperature environments of at least 60°F. For wet applications, ORAFOL Americas recommends using a medium-tack application tape when applicable for plotter cut graphics. After the application fluid has had ample time to dry, remove the application tape carefully at a 180° angle. newly applied graphics should remain in the application environment for at least 24 hours to promote uniform adhesion characteristics and allow any residual moisture to evaporate. (Recommended ingredients for wet application fluid: one tsp. of traditional Joy® or Dawn® dish detergent to on quart (32 fl oz.) of water. Detergent should not contain moisturizers, lotions, or bleaching agents.) Wet applications are not recommended or warranted when applying material with dispersion water-based adhesive systems such as ORAMASK®, ORACAL®, ORAJET® or ORALITE®; or films with RapidAir egress technology such as ORACAL®, ORAJET®, or ORALITE®. Ammonia-based products or other glass and surface cleaners should never be used to clean a substrate or as an application fluid for vinyl installation. Wet applications should only be used on clean, smooth, and non-porous surfaces.

What is the recommended wet application procedure for application to glass?

Glass and other surface cleaners may leave a residue that could cause poor adhesion between the graphic and the surface. Only clean glass with a mild detergent and water solution prior to vinyl application. The following Application Fluid recipe also works great as a general cleaning solution prior to application: one tsp. of traditional Joy® or Dawn® dish detergent to one quart (32 fl oz.) of water and 4-6 tbsp. of 70% Isopropyl Alochol. Shake well. If additional cleaning is needed, use only 70% Isopropyl Alcohol or ORAFOL® 359500030 Pre-Wrap Surface Cleaner to wipe down the surface. To learn more about ORAFOL® 359500030 Pre-Wrap Surface Cleaner, click here. Since glass is transparent, it is sometimes difficult to tell which side is contaminated when you are ready to clean. So it’s important to clean both sides of the glass to ensure you are removing any possible contaminants or debris that could potentially cause poor adhesion of newly applied vinyl graphics. Wet applications are typically recommended for large surface applications of solvent-based adhesive products being applied to architectural glass and windows. Wet applications are not recommended or warranted for the following: ORAFOL® flms utilizing /// ORAMASK®, ORACAL® or ORAJET® flms with polyacrylate dispersion (water-based) adhesive, all ORALITE® flms, ORACAL®, ORAJET®, ORALITE® flms with RapidAir® air-egress adhesive technology. ORAFOL Americas assumes no liability for glass breakage associated with application of its films on glass surfaces. For other tips to reduce the risk of poor adhesion properties and to reduce the risk of glass breakage, please contact ORAFOL Americas Product Support Specialists for suggested application guidelines.

How long should I wait before applying ORAFOL materials over One Shot® enamel paints on MDO board?

ORAFOL materials may be applied directly to One Shot® enamel paints when proper outgassing guidelines are followed. One Shot® recommends a (minimum) of four days at 60° F with proper air circulation to allow for proper paint outgassing. Please allow several more days if the ORAFOL film is printed and laminated. Both ORAFOL and One Shotۤ® recommend performing a test application prior to completing the intended job. Please contact ORAFOL Technical Support at techsupport-americas@orafol.com for further testing and outgassing procedures. (Please note that the paint curing process may take up to 30 days)

I hear it may take anywhere from 3-4 weeks for paint to cure on painted MDO board. Do you have any suggestions on bypassing this?

Unfortunately the paint curing process is very important for a successful vinyl application. If this is a substrate that is used on a regular basis, it may be beneficial to keep a few extra painted boards in stock that have had plenty of cure time. The idea is to have these in stock and ready to go for a successful and worry free vinyl application.

Is it ok to apply my ORAFOL vinyl directly to pre-primed MDO boards?

This would not be a good idea. The surfaces to which your ORAFOL vinyl films will be applied must be smooth, non-porous and thoroughly clean from dust, grease, or any contamination. Primer and flat paints are too porous of a coating and would collect dirt and moisture resulting in poor adhesion between the adhesive vinyl and the substrate. A smooth, properly cured, exterior rated semi-gloss finish would be ideal for vinyl application.

Can ORACAL® 751 High Performance Cast be applied to flexible substrates such as awnings?

Yes. Depending on the material that the awning is made of, ORACAL® Series 751 is often a good choice due to its conformability and durability. Be sure to watch out for awnings that contain waterproofing compounds or porous or textured surfaces, as these can retard adhesion. Always perform a 24-hour adhesive test on the actual substrate prior to completing the final installation.

What is the best cleaning solution to use for prepping substrates prior to application with ORAFOL films?

IPA (isopropyl alcohol) is generally recommended unless the substrate manufacturer states that there is an incompatability. Caution: many cleaning agents can leave a residue that either prevents vinyl adhesion or attacks the vinyl adhesive, such as Windex® and other glass or surface cleaners, Rapid Prep®, and degreasers.

What should I use if IPA (isopropyl alcohol) has been used to clean glass and there still seems to be a surface residue preventing vinyl adhesion?

We have found that Bon Ami® glass cleaner should remove any chemical residues left behind by other glass cleaners.

Which kind of ORAFOL films are suitable for making decals for automobiles?

ORAFOL offers a wide range of graphic marking films and digital media that are suitable for automotive decals. While you can obtain more specific application recommendations in the product section of our website, as a general rule we recommend the use of films with a solvent-based adhesive for automotive use. The solvent adhesive will last much longer when exposed to changing surface temperatures, chemicals and mild solvents. Also, our cast films tend to be more conformable and durable for demanding longer-term applications.

Is an adhesive promoter or tape primer required with ORAFOL film applications?

ORAFOL Americas does not promote or recommend using any type of adhesive promoter or tape primer with its Graphic Innovations or Reflective Solutions products. Use of adhesive promoters or tape primers will void any applicable warranty coverage.

Are there any metal surfaces that ORAFOL films should not be applied to?

Application and removal of ORACAL®, ORAJET®, ORAGUARD®, ORALITE® films applied to copper, tin, nickel, brass, lead, alloys, or magnesium will not be warranted. If a substrate is in question, please contact an ORAFOL Product Support Specialist prior to application.

What if the substrate is damaged after removal of the film?

ORAFOL Americas is not responsible for the integrity of the substrate to which the vinyl graphic is being applied, and will not be liable for any direct or indirect damage to the substrate caused during graphic installation, expected service life, or graphic removal. It is up to the graphic installer and their customer to determine the suitability and integrity of the substrate to which the vinyl graphic is being applied.

What is the recommended procedure for application to Flexible Substrates, like Banner or Flexface materials?

For the general warranty to apply with selected ORACAL® plotter films, the following procedures must be followed. Prior to application, the selected flexible substrate should be thoroughly cleaned with a clean saturated rag containing a mild detergent and water solution and then dried. The surface should then be wiped down with Isopropyl Alcohol or ORAFOL® 359500030 Pre-Wrap Surface Cleaner using a clean rag to remove any surface contamination such as dust, grease, or other debris. Application of a graphic marking film on a flexible substrate should be laid out on a rigid table top. After the initial application, graphics should then be burnished using a rivet brush. Multiple cycles of applying heat and pressure will help ensure a solid bond between the adhesive and the subtle texture of the substrate. (Always apply vinyl graphics to the smoother side of flexible substrates.) Graphics applied to previously used flexible substrates will not be warranted. ORAFOL Americas does not recommend applying printed and laminated graphics to flexible substrates.

What is the cloudy effect that sometimes presents itself on the surface of PSA vinyl films?

This cloudy effect is known as “Mottling” in the industry.

What is this?

- Mottling is a result of the plasticizers in the film migrating to the film surface, creating a cloudy or hazy appearance on top of the film.

Why does it happen?

- Sometimes, during various times of the year when there are broader temperature swings throughout the day – the material will become cloudy in appearance if going from (cold to hot) or from (hot to cold) during transit.

Is this a defect? Short answer: No…

- It may appear to be a defect, but it’s simply a chemical reaction and will rapidly disappear by simply subjecting the material to direct sunlight. You can also make cloudy mottled appearance to go away by applying heat from a heat gun or propane torch. The material will gloss back up and look completely normal in a matter of seconds or minutes.

Backlit Applications

What causes vinyl to bubble when applied to polycarbonate? How do I prevent this from happening?

Polycarbonate outgases for a period of time after manufacuring, which can cause bubbles in your vinyl. To prevent this, remove the protecting film as soon as possible and allow the polycarbonate to outgas naturally for at least 24 hours before applying the vinyl (longer if possible). Where practical polycarbonate should be baked 4-24 hours at 250° in an air-circulating oven before applying pressure sensitive vinyls. In some applications, flaming can be used. In all cases, however, see your manufacturer’s recommendations and guidelines.

What is the recommended procedure for drying out acrylic and ploycarbonate substrates?

When using substrates that tend to outgas, such as polycarbonate or acrylic products, it is recommended to remove the protective liner on these substrates to allow proper outgas time prior to installation. Either treat the substrate with a heat source or store it for 24-36 hours at room temperature conditions in order to cure the substrate prior to application of the vinyl graphic. Be sure to properly test these substrates by cleaning the surface and applying a small test strip for 24 hours. If bubbles or edge peeling appear, outgassing is still occurring.

Application Temperature

What is the recommended temperature for ORAFOL film application?

ORAFOL films should never be applied at temperatures below 46°F unless otherwise stated in the individual product technical data sheet. However, for best application results, surface and ambient temperatures should be between 65°-75°F; with humidity levels resting between 50 - 70%. Colder temperatures and lower humidity levels will result in the material feeling more rigid and the adhesive less tacky. Warmer temperatures and higher humidity levels will result in the material feeling more aggressive and pliable. Newly applied graphics should remain in the application environment for at least 24 hours to promote uniform adhesion characteristics. A significant change in temperature should be avoided during the first 24 hours after the application is initially complete, as this may result in the material lifting or popping up in complex curved areas.

Does ORAFOL recommend specific films for colder weather conditions?

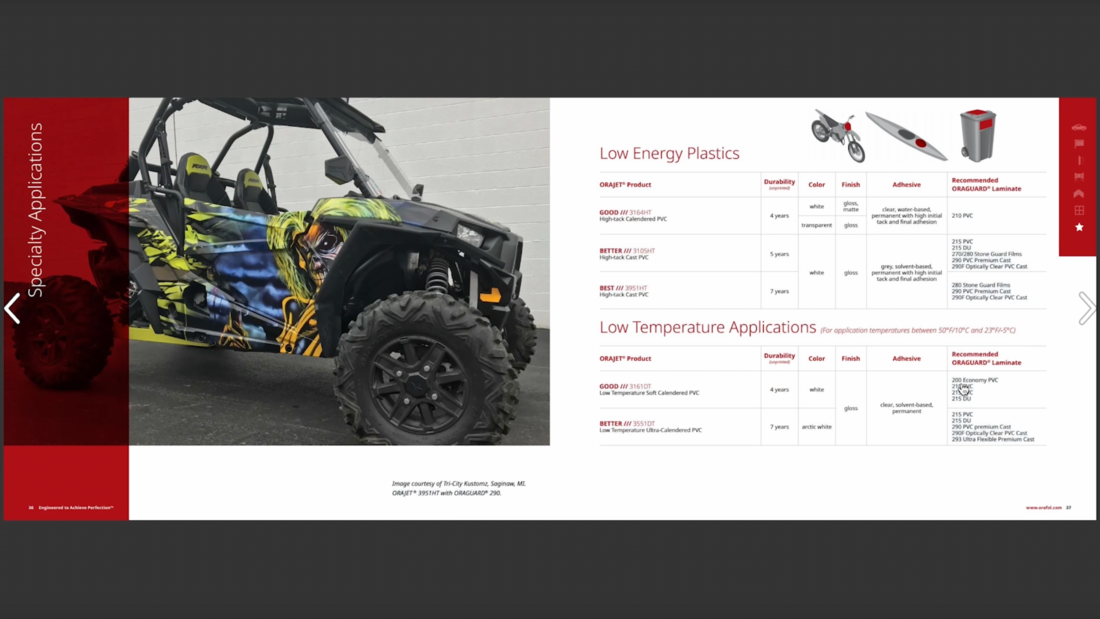

For colder application temperatures between 50°F/10°C and 23°F/-5°C please consider our (DT) Deep Temperature films, ORAJET® 3161DT or ORAJET® 3551DT.

Watercraft and Boat Applications

Does ORAFOL recommend any of its products for watercraft and boat applications?

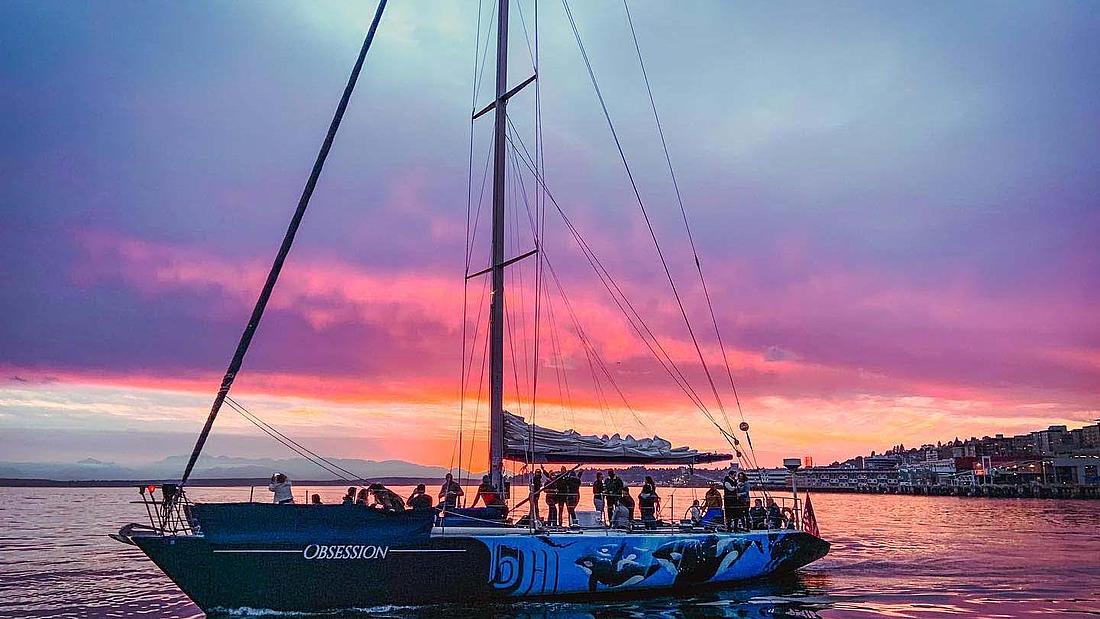

ORAFOL Americas recommends the following print media and over-laminate combinations, solid-color change, striping and lettering material options for applications to well-conditioned boat and watercraft gelcoats: Print Media Options: ORAJET® 3951, 3951RA, 3751RA, 3551, or 3551RA. Over-Laminate Options: ORAGUARD® 290, 290F, 293, 289F, 280, or 270. Solid-Color Change Wraps: ORACAL® 970RA. Striping and Lettering Applications: ORACAL® 951, ORACAL® 851, ORACAL® 751 or 751RA, or ORACAL® 383. Application on boats is generally not recommended below the water line. No warranty is given for applications under water. Additionally, no warranty is given for graphic applications to severly weathered or oxidized surfaces such as gelcoat, painted, or aluminum watercraft surfaces.

Does ORAFOL recommend under water applications?

Application on boats is generally not recommended below the water line. No warranty is given for applications under water. Additionally, no warranty is given for graphic applications to severly weathered or oxidized surfaces such as gelcoat, painted, or aluminum watercraft surfaces.

Wall Graphics

What is the best way to remove my wall decal (ORACAL® 631 Exhibition Cal) appropriately without damaging it so that I can use it again?

ORACAL® 631 can be removed from your latex painted wall by simply peeling up an edge of the graphic with your fingernail and slowly peeling it from the surface. Unfortunately, chances are the graphic will become distorted upon removal, and will not adhere to the wall very well when reapplied in another location.

Can I apply pressure-sensitive films over latex painted surfaces?

Over the past several years the paint industry has made significant changes to paint formulations in an effort to make less of an impact on our environment. Additionally, paint formulations are now more durable and contain additives that are designed to repel dirt and moisture. Consequently, this shift has made it more challenging to achieve a successful graphic installation to these new paint formulations.

Pay special attention to paint coatings that are listed as having the following attributes;

- Low-VOC

- Zero-VOC

Additionally, the following attributes would make it challenging for graphics to successfully adhere, and are considered “Hard-to-stick”

- “Stainblocking”

- “Washable”

- “Scrubbable”

These types of paint coatings may present adhesion challenges between the wall graphic adhesive and the paint coating, and may require the use of an ORAJET® material with solvent-based or high tack adhesive. Click here for complete Processing and Handling Interior Wall Graphic Instructions

Graphic Production

I am having trouble with my ORACAL® 631 releasing from the liner onto the application tape. What can I do to improve this?

There could be a couple of things happening with this situation. First check your vinyl plotter settings to make sure you aren’t cutting too deep into the release liner. If the silicone layer portion of the release liner is penetrated by the plotter blade it can cause the adhesive to migrate into the cut line. This creates an undesired bond between the release liner and the vinyl graphic. If this is consistent from one color to another, you may consider reducing the cut depth/pressure setting on the plotter. The idea should be to have the plotter blade cut through the face film and adhesive layers and barely score the surface of the silicone layer portion of the release liner. After applying application tape, place the graphic face down on a rigid table top so you are viewing the back of the release liner. Apply pressure with the squeegee back and forth several time over the back of the release liner. This will help push the adhesive out of the cut line and also create a stronger bond between the vinyl graphic and the application tape. It can be difficult to pull the graphic from the release liner, so it may be easier to remove the release liner from the graphic while the graphic is face down on a rigid table top. It is also important to use a high tack application tape such as ORATAPE® HT55 which was designed specifically for use with ORACAL® 631. If you need further assistance with troubleshooting please contact ORAFOL Product Technical Support directly.

Can ORACAL® graphic marking films vary in color from lot number to lot number?

Yes, for graphic applications of the same color on a single substrate, ORAFOL recommends using material from the same lot number. If materials from different lot numbers have to be used, the user must check prior to application whether any differences between the lot numbers will affect processing of the films and/or impair the final result.

At what temperature do I store my rolls of ORAFOL materials? Do temperature variations affect the vinyl film while still on the roll?

The self-adhesive products ORACAL®, ORAJET®, ORAGUARD®, ORABOND®, ORALITE®, Reflexite® and ORAMOUNT® are supplied in rolls and should at all times be stored either suspended or standing on end on the roll blocks provided, and never lying on the material's side. For storage and processing they should be kept in a cool dry place protected from sunlight. Relative air humidity between 50% and 60% and temperature between + 64°F and 72°F should be ensured. Direct sunlight, storage beside radiators, etc. should be avoided. Please observe the shelf life instructions contained in the technical data sheet available for each product.

Are there specific color profiles I should be using with ORAJET® materials?

Yes, make sure to load the correct media profile for your job, based on your specific combination of media, ink, printer and RIP software. Each series of ORAJET® digital media requires different print and RIP software parameter settings due to its individual qualities, such as thickness of the adhesive layer and face film. Download a wide selection of FREE color profiles here.

Will my printed ORAJET® materials be warranted when using a liquid laminate to protect my prints instead of ORAGUARD® laminating materials?

No warranty will apply when combining any ORAFOL films with other manufacturers of pressure sensitive adhesive graphic marking films or liquid laminate coatings.

Does ORAFOL offer custom colors? Can you match a Pantone color?

ORAFOL can produce custom colors for most products, however there are minimum order requirements and possibly additional costs based on order volume. For specific inquiries, please contact your respective ORAFOL Americas Territory Sales Manager.

What type of laminate should I use for my prints on ORAJET® media?

ORAGUARD® laminating films are designed to match specific ORAJET® digital media. For specific recommendations, refer to the Digital Inkjet Media Selection Guide. When using solvent inks, we recommended allowing a minimum of 24 to 48 hours for the ink to cure before laminating. Failure to follow this practice can cause bubbles, delamination, discoloration, shrinkage and difficult application due to increased adhesive properties.

Can environmental conditions affect vinyl releasing from a liner?

All cut, weed, mask and release operations are subject to environmental conditions. High humidity and heat conditions can make application more difficult. In these cases a higher tack application tape(such as ORATAPE® HT55) may help. If plotted graphics are not weeded quickly after production, adhesive may flow into the cut line, making weeding more difficult.

I want to know if ORAFOL films contain acid because I want to use the vinyl for my scrapbooking projects.

No, ORAFOL films do not contain acid. They will work great for your scrapbook projects.

Does ORAFOL offer stencil mask films? If so, are any of them translucent?

Yes, ORAFOL Americas offers 4 different stencil mask films…ORAMASK® 810, 810S, 811, and 813. ORAMASK® 810 is a conformable stencil film that is useful for spraying and painting on uneven surfaces. It comes in a transparent grey color. ORAMASK® 810S has a solvent-based adhesive that is ideal for multi-color or solvent-based paints. It is highly conformable and comes in transparent grey. ORAMASK® 811 is a rigid paint mask film for painting or spraying on even surfaces that is available in opaque white. Lastly, ORAMASK® 813 is a translucent rigid stencil film for painting or spraying on even surface areas that is available in translucent blue.

Can I clear-coat ORAFOL vinyl graphics?

Clear-coating materials such as liquid laminate may provide additional protection for vinyl graphics, but caution should be used because solvents in some varnishes can attack the vinyl and/or adhesive, causing failure. When in doubt, use the matched ORAGUARD® cold laminating films.

Can I print on ORACAL® brand films with a thermal-transfer printer?

Many ORACAL® plotter films including Series 651 and Series 751 are engineered to perform well with thermal-transfer printers.

What ORAFOL media can be used with dye and/or pigmented inks?

ORAFOL does not currently market films designed for use with water-based ink sets.

What pressure should I have my vinyl cutter set on when plotting ORACAL® vinyl films?

There are many different types of plotters in use. You should run a test to ensure that your blade pressure and speed are properly adjusted for ORAFOL's higher density films. When testing different pressure and speed settings, look for how easy the graphic weeds, making sure not to cut too deep. Also, make sure that the vinyl cleanly releases from the liner using transfer tape. If cut too deep, the vinyl will be difficult to release from the liner, and may cause tearing along the edge of the cut.

What application tape do you suggest when using ORACAL® plotter films?

We recommend a high tack application tape, such as ORATAPE® HT55 for most of our plotter films. The relationship between the release liner and the vinyl is different for every vinyl manufacturer. ORAFOL’s vinyl has a tight liner adhesion. The tight liner adhesion improves the weedability of the vinyl. If what you’re using works for you, continue to use it. Other tips we suggest include squeegeeing on the reverse side (the back of the liner) and pulling the release liner away with the application tape side down.

Will ORACAL® films work on my plotter?

Check the technical specifications for the ORACAL® Series that you are interested in purchasing to see if it is compatible with your brand of plotter. You may also want to run a test cut to ensure that your blade weight is properly adjusted for ORAFOL’s higher density.

Are ORAFOL's films enamel receptive?

Many enamel coatings, as well as airbrush paints, bond well to ORAFOL films, but we recommend testing your specific brand of paint. KRYLON® enamel paints tend to work very well. One Shot® paints require the use of One Shot® Vinyl Primer.

What is the recommended outgas procedure for Solvent and Eco-Solvent Inks?

When using ICC Color Profiles downloaded from www.orafol.com, ORAFOL Americas recommends allowing printed films at least 24 hours at 70°F to dry (outgas) before applying a laminate to avoid delaminating or adhesive failure (48-72 hours preferred). Note the following considerations: 24 hours of dry (outgas) time should be considered the minimum before applying lamination. (Prints with very little ink coverage would fall into this category.) If the print is heavy in ink saturation, (darker, rather than lighter) a longer outgas time of 48-72 hours is preferred for the print to dry before lamination. Using third-party inks and generic color profiles may result in poor printing quality, and require more time to effectively dry (outgas). DO NOT leave the graphic rolled up tightly around the core after printing. This will cause the solvent gasses in the inks to be trapped and potentially migrate to the adhesive layer of the material, resulting in poor adhesion properties once applied to the intended substrate.

Does ORAFOL warrant the use of 3rd-party inks with it's ORAJET® Digital Print Media?

ORAFOL Americas only warrants the compatibility of OEM solvent, eco-solvent, latex, and UV curable ink-sets with its approved inkjet printable materials. Each series of ORAJET® digital media requires different print and RIP software parameters because of the individual qualities of each material. Check the Support section of our website for a wide selection of FREE color profiles.

What are the benefits of applying an over-laminate to my vinyl graphic?

Lamination of inkjet prints is recommended to ensure longer lifespan at optimum quality (gloss, color, physical damage). ORAGUARD® laminate films enhance the desired appearance of the graphic (gloss, semi-gloss, matte). They also provide excellent protection against ink fading from exposure to UV rays.

How can I find out more information about product combinations and performance?

Please contact ORAFOL Americas Product Support Specialist to discuss proper product combinations, and substrate compatibility for your specific job. No warranty will apply when combining ORACAL®, ORAJET®, ORAGUARD®, and ORALITE®, branded films with films produced by any other manufacturer. For a list of compatible ORAJET® and ORAGUARD® combinations, along with application recommendations, please review the ORAFOL Graphic Innovations Digital Inkjet Media Selection Guide.

Purchasing

Do you have any authorized distributors in India?

ORAFOL America’s market area includes the U.S., Canada, Mexico, Latin America and the Caribbean. India and other international markets outside of our market area are served by ORAFOL EMEA. You can contact them here.

I would like to know if there are any suppliers in Canada where I can purchase ORAFOL products.

We have distributors located throughout Canada. You can contact them here. “Search by Region” > Choose “Country” > Choose “State/Provence”

I would like to know if there are any suppliers in Latin America and the Carribbean where I can purchase ORAFOL products.

We have distributors located throughout Latin America and the carribbean. You can contact them here. “Search by Region” > Choose “Country” > Choose “State/Provence”

ICC Profiles

Select manufacturer below to find the right ICC profile.

Disclaimer

The colour profiles provided on this site are provided solely as a resource for customer use only.

Due to the individual nature of printing systems, inks and software, and the environments in which printing systems operate, it is the customer`s responsibility to determine the suitability of use of any profile with their print system.

ORAFOL Europe GmbH does not provide any warranty or guarantee, expressed or implied, associated with the use of these profiles, and is not liable for any loss or damage incurred pursuant to the use of such profiles.

Printing Recommendations

ORAFOL has tested and partially profiled (see ICC profile download) the digital printing and printing materials listed on this website with the most common printing, colour and ink systems.

Given the wide variety of different printing and ink systems available in the market, users should test the suitability of our films for their systems. Users should also use the recommendations made by the printer and ink manufacturers.

When placing your order with us, please indicate printer-specific winding or roll core requirements in your order.

More information

You can always contact our customer service team, if you need more specific printing recommendations.

Colour Palettes for Graphic Design Software

Disclaimer

ORAFOL Europe GmbH does not provide any warranty or guarantee, expressed or implied, associated with the use of these profiles, and is not liable for any loss or damage incurred pursuant to the use of such profiles.

Digital Colour Cards for ORACAL® Products

Find available colours, structures, and finishes along with product details

Colour Cards (36 Products)

ORACAL® 970RA

Craft - Premium Wrapping Cast with RapidAir® Technology VinylORACAL® 751C

Craft - High Performance Cast VinylORACAL® 951

Craft - Premium Cast VinylORACAL® 351

Craft - Metalized Polyester VinylORACAL® 352

Craft - Print Polyester VinylORACAL® 383

Craft - Ultraleaf Cast VinylORACAL® 8810

Craft - Frosted Glass Cast VinylORACAL® 8510

Craft - Etched Glass Cal VinylORACAL® 6510

Craft - Fluorescent Cast VinylORACAL® 8300

Craft - Transparent Colored VinylORACAL® 975

Craft - Premium Structure Cast VinylORACAL® 631

Craft - Exhibition Cal VinylORACAL® 651

Craft - The Industry Leading VinylORACAL® 851

Craft - Sparkling Glitter Metallic VinylORACAL® 641

Craft - Economy Cal VinylORACAL® 651

Intermediate CalORACAL® 951

Premium CastORACAL® 970RA

Premium Wrapping CastORACAL® 351

Polyester FilmORACAL® 352

Print PolyesterORACAL® 383

Ultraleaf CastORACAL® 631

Exhibition CalORACAL® 641

Economy CalORACAL® 751C

High Performance CastORACAL® 751RA

High Performance Cast Film with RapidAir TechnologyORACAL® 851

Sparkling Glitter MetallicORACAL® 970RA

Premium Shift Effect CastORACAL® 970RA

Premium Special Effect CastORACAL® 975

Premium Structure CastORACAL® 6510

Fluorescent CastORACAL® 7510

Fluorescent Premium CastORACAL® 8300

Transparent CalORACAL® 8500

Translucent CalORACAL® 8510

Etched Glass CalORACAL® 8800

Translucent Premium CastORACAL® 8810

Frosted Glass Cast